weekly meeting

→

Europe/Zurich

3162/2-C01 (CERN)

- 2023/09/26

- Agenda : https://indico.cern.ch/event/1328547/

- Present :

- EN-MME : Carlotta, Audrey, Benoit, Laurent, Didier

- ATLAS-TC : Martin, Jan, Raphael

- Carlota gave the status of the calculation

- Support bracket

- thickness calculation - load cases summarized (still in draft version)

- flexibility analysis of the tube - preparing the report, expected to be finished next week

- Calculation on pipe fittings according to the norm (NF-EN-10253-4) has demonstrated that the T-junctions are note validated. Reduction of the section is not possible because for the early run the flow shall be respected. Therefore EN-MME will develop an ad'hoc T junction for the first two line that will be used for the early commissioning.

- ATLAS TC validate the fact that the vacuum shall be consider in the simulation for the pressure test.

- Installation

- For the transport of the material on spot from UX15 or USA15, Raphael will be the contact person with the transport team.

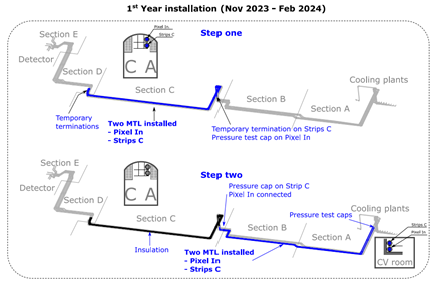

- We agreed that if possible additional lines could be assembled provided that this is not delaying the objective to have the 2 first MTL installed up to USA 15-CV.

- EN-MME propose to use butt weld to joint adjacent pipe on straight section instead of the sleeve. This modification with allow a gain in installation time, will increase the quality as the butt weld can be X-ray tested. ATLAS TC validate this proposal.

- Sequence of welding installation

- Installation in section C (prepared in the workshop)

- Installation in junction between section C and B (prepared in the work-shop)

- Installation in section B and section A (along the wall) (prepared in the work shop)

- Finish with the connection of the 2 sections (adjustment on the field)

- Thermal insulation

- Due problems on the offers of the thermal insulation the order went out of CERN yesterday. Delivery date XXX

- Brackets :

- The first order of bracket concerns :

- 9 x MTL SUPPORT ZC1 ATFEOM__0011 IN 304

- 3 x MTL SUPPORT ZC2 ATFEOM__0019 IN 304

- 1 x MTL SUPPORT ZB2 ATFEOM__0036 IN 304

- The first order of bracket concerns :

The delivery is foreseen for end of October ?

- EN-MME inform that the bracket ZB1 can be launch in production

- x 4 -MTL support ZB1 ATFEOM__0025

ATLAS TC will take care of this order

- EN-MME has noticed that the wall in USA15-CV and in USA15 are not co-planar and generate (on CAD model) some conflict between the MTL and the wall in USA15-CV.

- ATLAS TC will verify on spot if moving the line by 150mm could be a solution regarding the access in the area

- Design brackets that can compensate this 150mm misalignment and route the MTL accordingly (EN-MME)

- To ease the CAD positioning ATLAS TC will try to better position the scan to each other

- EN-MME presented the integration of the support bracket in the USA15-CV attached to the sealing. ATLAS-TC will check the conflict with the EN-EL cable tray and will provide feedback to EN-MME. (EN-MME integration model ST1710899). The design of this bracket is the priority to allow the possibility to install the lines during the YETS.

- ATLAS TC suggested to use the supporting pillars in the USA 15-CV as fix point close to the stations. ATLAS-TC inform that the thermal expansion of the line between the fix point (pillar) and the plant can be compensated by the dog leg that equip each line connected to the plant. EN-MME suggested to bring the HGTD line closer to the pillar, ATLAS TC integrate this modification in the ATLAS CAD model.

There are minutes attached to this event.

Show them.