LVPS TM with WIENER #5

→

Europe/Zurich

Present: Marcel, Daniel, Krzysztof

There was important technical discusison brought on this meeting with 2 main topics:

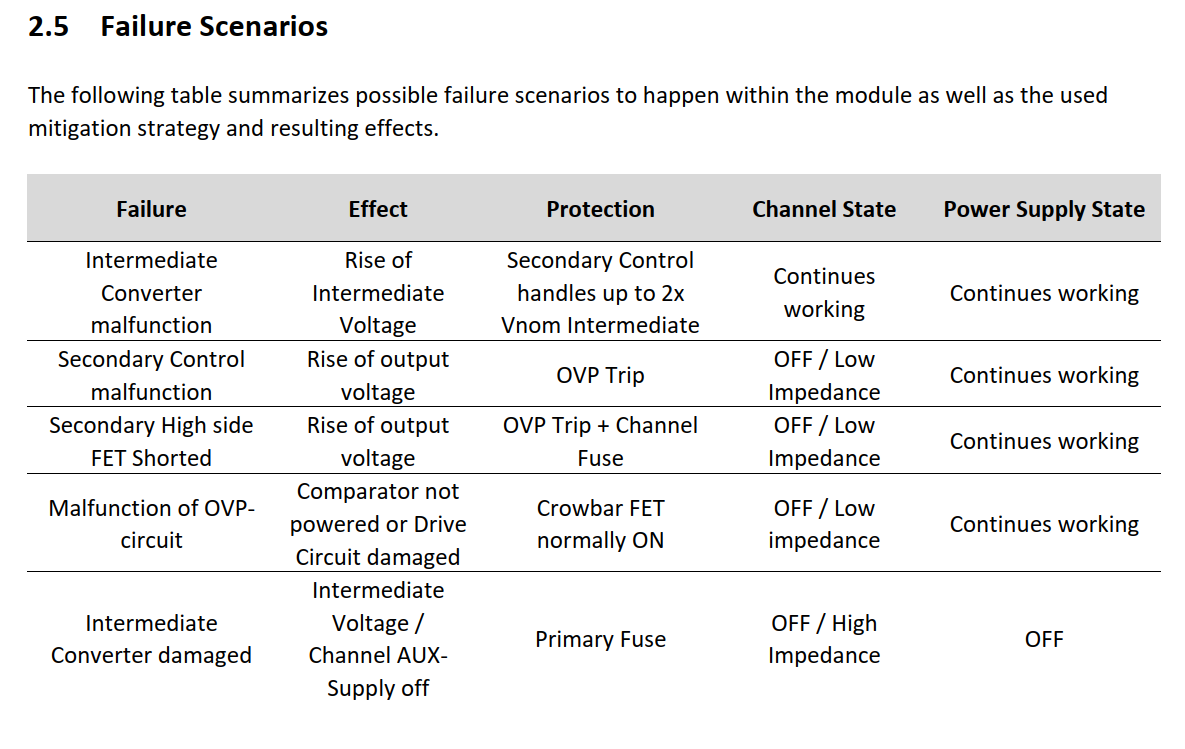

1) At some point in the design phase, crowbar resistor was changed from very low few ohms resistance to much higher resistance (68 Ohm). This was done to mitigate the negative voltage peak when crowbar was activated in the past to avoid damage of OP-AMP measuring voltage / current. This change, however, has a consequence of not protecting the load in the case of some scenatios, where DC-DC converter fails and tries to deliver higher voltage. This makes point 2.5 of design file [1] incompatible with current version in some scenarios, where over-voltage protection should take the entie current and blow the fuse upstream. The most worrying scenario is hi-side FET conducting scenario, where full voltage of LLC stage appears at the output. High impedance crowbar will not burn the fuse nor lower the voltage.

Wiener should make assesment communicate to us whether we may revert to very low impedance for the crowbar. Also, input fuse for the step-down stage was increased at some point thinking it is necessary, but it seems that it has also consequences and the value must be lowered back.

2) Inrush currrent test:

Wiener showed internal report showing the measurements. On the first glance, it looks compatible with simulations - cold start with NTC resistors limiting inrush current are working properly and no excessive transient was measured.

This test, however should be extended:

a. There should be inrush current measurement made assuming a hot start with a few intervals. For instance, LVPS module is operating with 100% of its module. Then it shuts down. After a defined interval (example; 30s, 1 min, 2 mins) inrush current should be measured. At that point resistance of the NTC resistor is much lower and the inrush current eak will be also drastically higher.

b. To improve voltage measurement across the shunt reisstor, positive terminal should be grounded to bring this potential close to PE of the scope, to limit CMRR influence on the measurement. Alternatively, a contact-less current probe could be used.

3) WIENER should provide a short report with basic information about thermal test on the entire chassis for completeness of the documentation.

[1] section 2.5 of design file