MINUTES:

Update on on-going activities:

- Bearings reaction tooling assy.

- We should provide some numbers on the thermal expansion mismatch between the horizontal bearings position and the central fixed plate. Proposal is to use a plate/shims with same materials as the bearing axis. But may be not needed. Action item: Check numbers and take action.

- Side plates to block the assembly during manipulation

- Federico is doing the computations for lifting the assembly (results to be stored)

- 1 week to complete production drawings (ready for mid next week), including feedback from simulations

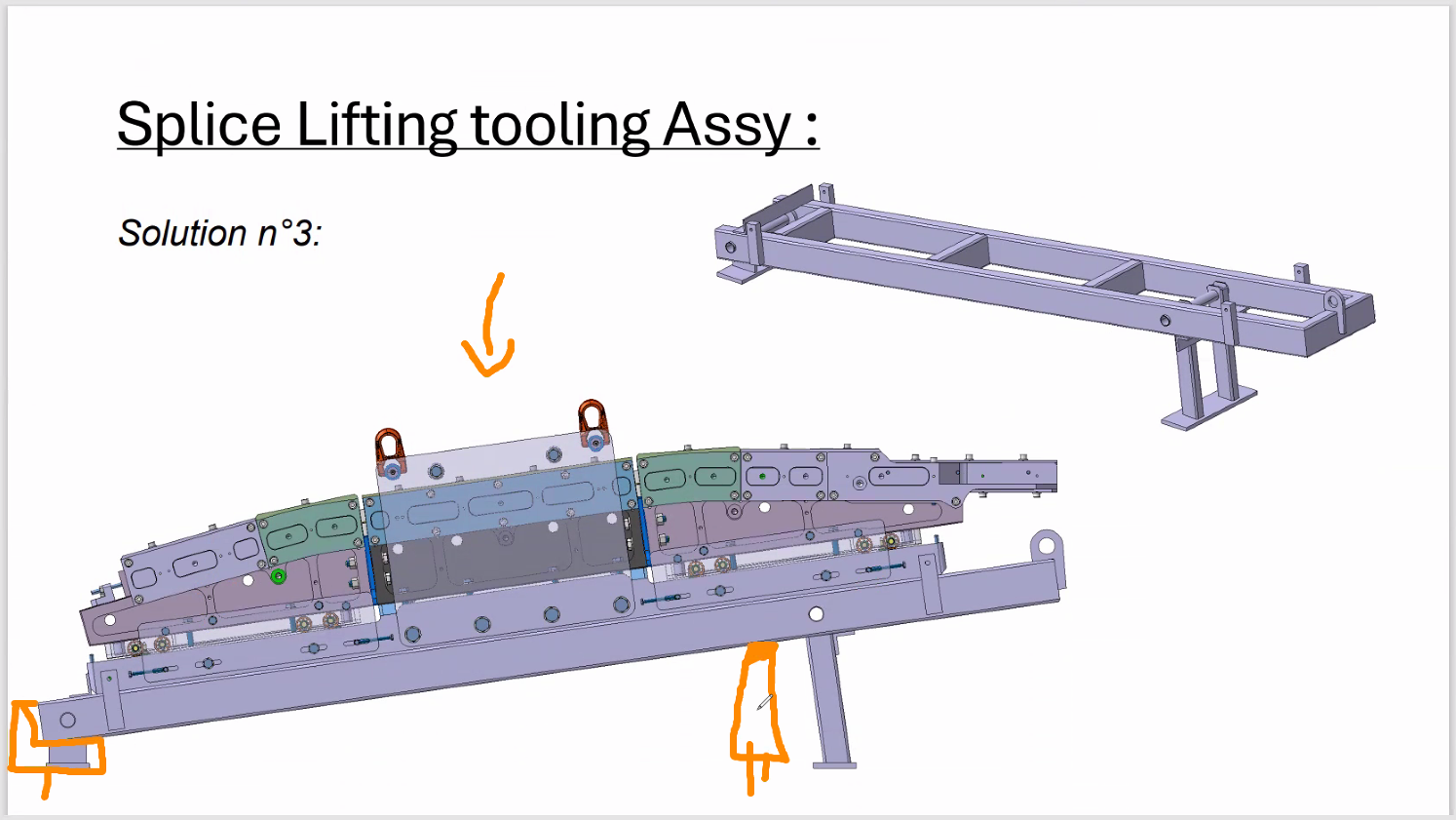

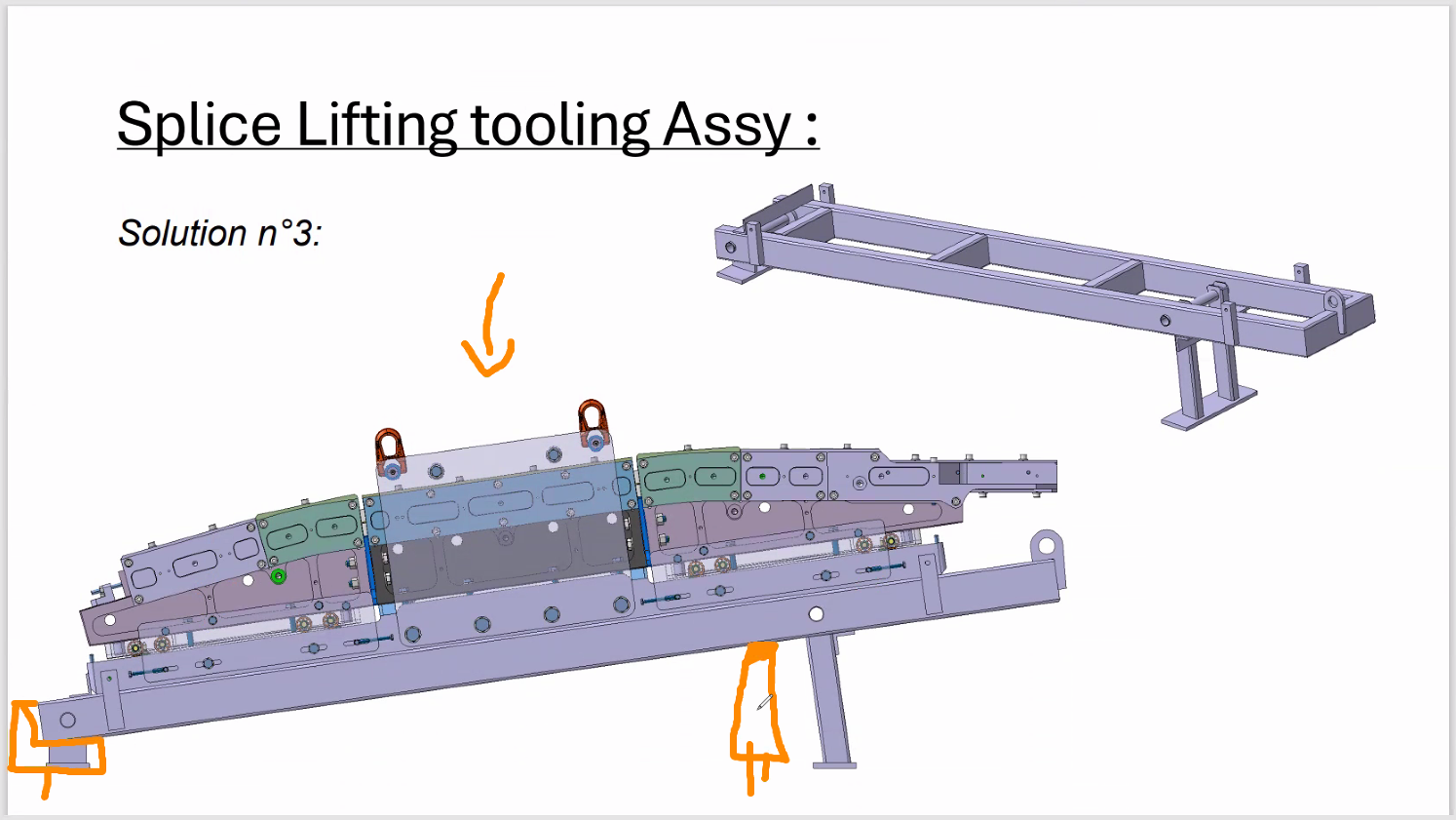

- Lifting tooling

- The current solution considers 4 bolts that take all shear when lifting. Consider adding pins instead and just bolts for joining.

- Tooling positioning for splicing. (In FRESCA this operation was tricky, Tin was migrating due to inclination)

- Solution 1 - Tilted frame (bolted)

- Solution 2 - Tilted frame with feets (quick axle release)

- Solution 3 - Welded frame

- Proposal - Design two feets (tooling) to fit directly on the available assembly tables at B.927

- Magnet lifting

- 2 solutions

- Proposal - Alternative solution with spacers and eyebolts (or dedicated ears) on both yoke extremities that are pinned and bolted.

- Splicing tooling

- Well advanced

- See last week's minutes

- 150 mm for the splice length (pitch is 124 mm for the last cable version) - 30 mm more than pitch, consistent with MQXF

- Drawings

- Added the stress relieving data for parts

Mechanical structure:

- For BOND, do not consider the active and passive bladder solution. Try instead to make the encapsulation the thinnest.

Racetrack coil mock-up:

- RHT cycle finished. The mock-up will be recovered from the oven tomorrow. Oscar will post-process the data as soon as possible.

There are minutes attached to this event.

Show them.