CEC-ICMC 2019 - Abstracts, Timetable and Presentations

Connecticut Convention Center, Level 6

The Technical Program can be accessed via the Timetable Views on the left.

- All PLENARY sessions and Awards Presentations will be held in the Marriott Ballroom at the Hartford Marriott Downtown Hotel.

- Oral session M3Or4A – Joint CEC & ICMC Session: Transportation Overview (Wednesday, July 24, 4:15 – 6:20 PM) will also be held in the Marriott Ballroom at the Hartford Marriott Downtown Hotel.

- All OTHER sessions, the Exhibit and social events will be held on Level 6 of the Connecticut Convention Center.

Any individual presenting at and/or attending CEC/ICMC 2019 must be a registered participant. Click here for registration information.

If you have a presentation, you must first login via the upper right corner; then and click on “My Contributions” below “Presentation(s)”.

All presenters are encouraged to upload an electronic copy of their poster in .PDF format prior to their presentation at the scheduled CEC/ICMC’19 session. Presenters of oral talks MUST ALSO submit their presentation file to the Speaker Ready Room one (1) day prior to their scheduled presentation.

Session ID’s & Presentation ID’s

The first character of the session ID, C or M, represents the Conference designation, C for the CRYOGENIC Engineering Conference (CEC), M for the International Cryogenic MATERIALS Conference (ICMC). The second character, 1, 2, 3 or 4, denotes the day of the Conference: Monday, Tuesday, Wednesday or Thursday. The third and fourth characters (Or or Po) indicate whether the presentation is in an oral or poster session. The fifth character represents the morning or afternoon time slot and the last character, A-G, differentiates the sessions on a given day. The presentation ID consists of the session ID plus the order within the session. Session ID examples are: C1Po1A (CEC Poster on Monday); M1Or1A (ICMC Oral on Monday). Presentation ID examples are: M1Or1A-01; C1Po1A-01.

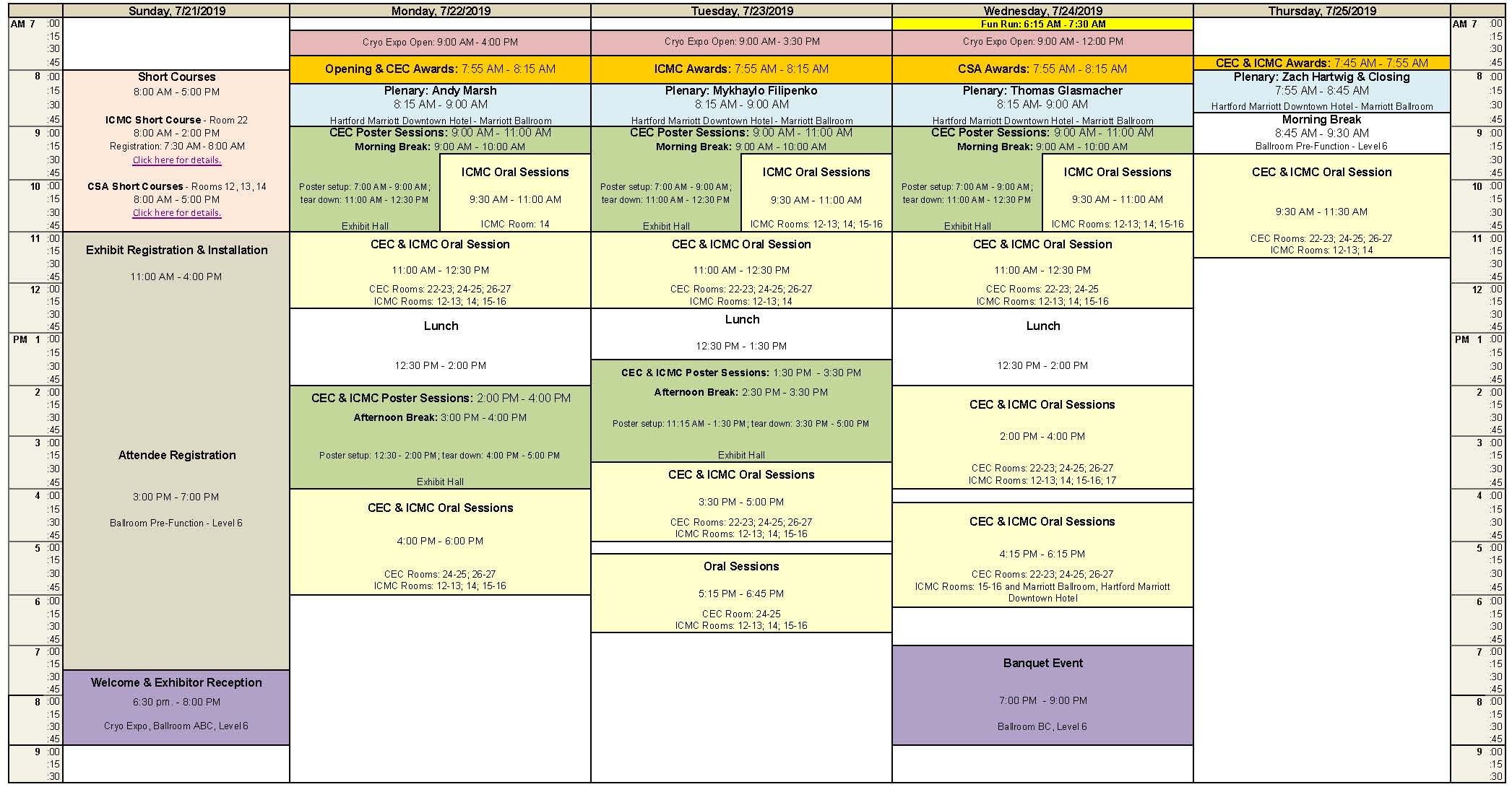

Click on the image below to download the Schedule at a Glance in PDF format.

All other conference information can be found on the CEC/ICMC'19 website at http://www.cec-icmc.org.

-

-

08:00

Cryogenic Society of America (CSA) Short Courses Level 6, Rooms 12, 13, and 14 (Connecticut Convention Center)

Level 6, Rooms 12, 13, and 14

Connecticut Convention Center

Visit https://www.cec-icmc.org/csa-short-courses/ for details.

-

08:00

ICMC Short Course Level 6, Room 22 (Connecticut Convention Center)

Level 6, Room 22

Connecticut Convention Center

Visit https://www.cec-icmc.org/conference-program/icmc-short-course/ for details.

-

15:00

Registration Open Level 6, Ballroom Pre-Function Area (Connecticut Convention Center)

Level 6, Ballroom Pre-Function Area

Connecticut Convention Center

-

18:30

Welcome & Exhibitor Reception Level 6, Cryo Expo Exhibit Hall (Connecticut Convention Center)

Level 6, Cryo Expo Exhibit Hall

Connecticut Convention Center

-

08:00

-

-

07:45

Registration Open (7:00 AM - 5:00 PM) Level 6, Ballroom Pre-Function Area

Level 6, Ballroom Pre-Function Area

-

07:50

Cryo Expo Open - 9:00 AM - 4:00 PM Level 6, Cryo Expo Exhibit Hall

Level 6, Cryo Expo Exhibit Hall

-

07:55

Opening & CEC Awards (7:55 AM - 8:15 AM) Marriott Ballroom (Hartford Marriott Downtown Hotel)

Marriott Ballroom

Hartford Marriott Downtown Hotel

-

Plenary: Andy Marsh | Plug Power, Inc. Marriott Ballroom (Hartford Marriott Downtown Hotel)

Marriott Ballroom

Hartford Marriott Downtown Hotel

Conveners: Jacob Leachman (Washington State University), Jennifer Marquardt (Ball)-

1

C1PL01: The Growing Hydrogen Economy and the Need for Liquid Hydrogen

McKinsey has estimated that hydrogen could account for one-fifth of the total energy consumed by 2050. In 2030 it is envisioned that over 10-15 million automobiles and 500,000 commercial vehicles could be powered by hydrogen. Liquid hydrogen is potentially very attractive for fuel delivery as well as on-board vehicle usage in the transportation segment. There are challenges today including storage costs, evaporation rate, energy consumption and safety in deploying liquid hydrogen. This talk will explore the opportunities for liquid hydrogen in mobility as well as the challenges facing engineering companies today in deploying liquid hydrogen in the transportation segment.

Speaker: Andy Marsh (Plug Power Inc.)

-

1

-

09:00

Morning Break (during Poster Session) Level 6, Cryo Expo Exhibit Hall

Level 6, Cryo Expo Exhibit Hall

-

C1Po1A - Cryogenic Rotating Machinery Level 6, Cryo Expo Exhibit Hall

Level 6, Cryo Expo Exhibit Hall

https://whova.com/portal/webapp/cecic_202107/Artifact

Conveners: Philipp Arnold (European Spallation Source ESS AB), Weibo Chen (Jet Propulsion Laboratory)-

2

C1Po1A-02 [23]: A novel hydrogen turbo-expender with active magnetic bearings and an eddy current brake

A cryogenic expander for hydrogen liquefier with active magnetic bearings and an eddy current brake was designed and will be made and tested. The shaft design and strength review is very important factors for the turbine since it affects the performance and safety of the expander significantly. In order to product lower temperature hydrogen, the liquefier needs a very small and high-speed turbo-expander. But there are few studies of expander with both active magnetic bearings and eddy current brakes. In this study, the speed of the turbine is up to 100000 rpm. Its cooling power is 3kw. The inlet pressure is 1Mpa and the outlet pressure is 0.8Mpa.Under this condition, the turbine was designed and the simulation was done via COMSOL Multiphysics.

Speaker: Prof. Jihao Wu (1.Technical Institute of Physics and Chemistry Chinese Academy of Sciences. 2.University of Chinese Academy of Sciences) -

3

C1Po1A-03 [22]: Effect of Leading-edge Geometry and Thickness on The Performance of Miniature Cryogenic Expansion Turbine

The numerical simulation included solid blades with four different leading-edge thicknesses and four different leading-edge geometries. One of the geometries was square, one was ellipse a(ellipse ratio is 1), one was ellipse b(ellipse ratio is 2), and the other was ellipse c(ellipse ratio is 3). The four thicknesses were 0.7mm, 0.6mm, 0.5mm, 0.4mm. The results show increased efficiency loss for increased leading-edge thickness for square geometry. For ellipse geometries, there was no significant difference when the leading-edge thickness changed at the positive incidence range. For the same leading-edge thickness(0.7mm), square leading-edge caused more loss than ellipse leading-edge. For square geometry, the optimal incidence angle was about -8 degree(0.7mm). For ellipse geometries, the optimal incidence angle was about -30 degree(0.7mm). And with the decrease of leading-edge thickness, the square's optimal incidence angle was toward to zero degree, the ellipse's optimal incidence angle was toward to larger negative angle.

Speaker: Changlei Ke -

4

C1Po1A-04 [21]: Design and Experiment Study of Cryogenic Helium Turbine Expander

Cryogenic helium turbine expander is a core component of large helium refrigerators and liquefiers. Two-stage cryogenic helium turbine expanders are designed for 250W@4.5K helium refrigerator. One-dimensional design have been done based on the parameters calculated by the process. According to the geometric parameters calculated by the one-dimensional design, a new modeling method is adopted to design the blade shape of the expander. The two stage turbine expander are successfully applied to 250@4.5K helium refrigerator, and the efficiency of the two expander are higher than 65%.

Speaker: Dr Kongrong Li (Technical Institute of Physics and Chemistry) -

5

C1Po1A-07 [19]: Study on the Load Capacity of New Type Gas-lubricated Spiral-Groove Thrust Bearing

Absrtact: The influence of the number of grooves, the spiral angle, the groove depth, the ratio of length and width of spiral-groove thrust bearing on bearing capacity is analyzed by using fluent fluid computing software, and the influence of two new parameters---slope angle and internal spiral line---on load capacity of spiral-groove thrust bearing is also simulated, the parameters of spiral groove gas bearing are optimized to solve the maximum load capacity gas-lubricated spiral-groove thrust bearing. The results show that there is an optimal value for slope angle and internal spiral line to maximize the load capacity.

Key words: spiral groove; conventional parameters, the slope angle, the internal spiral line, load capacitySpeaker: Dr Xiaohua Zhang -

6

C1Po1A-08 [18]: Test of a submersible liquid helium transfer pump

Most laboratory scale helium plants use pressurization of the storage Dewar to achieve the subsequent transfer of the liquefied helium. The unavoidable throttling in the transfer line in combination with cold gas displacement leads to high flash gas losses of up to 30 % of the transferred helium. Furthermore, filling rates are limited. A transfer pump in combination with a double-flow transfer line can overcome these shortcomings. A test setup was established between two mobile Dewars. This allows assessing basic performance parameters of the pump. An overview of the setup and first measurement results are presented.

Speaker: Steffen Kloeppel (TU Dresden) -

7

C1Po1A-09 [17]: Development of a cryo-rotary joint for thermosyphon cooling system up to 1000 rpm

Electric propulsion systems with MW-class output power density are expected to reduce fuel consumption of the current passenger aircrafts. In this scheme, motors and generators should have an output of 4000-30000 hp and capable of high-speed rotation. A high-temperature superconducting motor fitted with an adequate cooling system has the potential to achieve the requested efficiency and high-power density. The cooling system is required to maintain the operating temperature under high-speeds, over 1000 rpm. The cryo-rotary joint is an integral part of the cooling system as it is necessary to provide refrigerant to the evaporator in the rotor. However, the cryo-rotary joint generates heat as a function of rotating speed. The heat is significant at high-speeds and it affects to both efficiency and the cooling system. To solve this problem, we developed the cryo-rotary joint which has a structure to suppress the heat generation. The new cryo-rotary joint was installed for a neon thermosyphon cooling system to evaluate its performance at speeds up to 1000 rpm.

Speaker: Mr Kota Yamaguchi (Tokyo University of Marine Science and Technology) -

8

C1Po1A-10 [16] (Jiaho Wu) - Presentation Withdrawn

-

2

-

C1Po1B - Aerospace Applications Level 6, Cryo Expo Exhibit Hall

Level 6, Cryo Expo Exhibit Hall

Conveners: Jacob Leachman (Washington State University), Adam Swanger (NASA Kennedy Space Center)-

9

C1Po1B-01 [14]: Robotic Refueling Mission 3—An Overview

Robotic Refueling Mission 3 (RRM3) is an external payload on the International Space Station (ISS) to demonstrate the techniques for storing and transferring a cryogenic fuel, specifically methane, on orbit. The RRM3 Source Dewar was filled with ~19 kg (~42 liters) of liquid methane on October 28, 2018 and has been maintained with zero boil-off using a mechanical cryocooler since that time. RRM3 was launched from the Kennedy Space Center on SpaceX Commercial Resupply Service (CRS) 16 on December 5, 2018 and berthed on the ISS Express Logistics Carrier on December 15. Methane is transferred from the Source Dewar to a Receiver Dewar through one of three transfer lines—one hardline that was established when the system was built and two flexible lines that will require robotic operation prior to the transfer. RRM3 was designed and built at NASA Goddard Space Flight Center (GSFC). Initial testing was performed at GSFC using liquid nitrogen and liquid argon. Final testing and flight fill of methane was performed at the NASA Kennedy Space Center (KSC) because KSC has the necessary facilities and expertise for handling a combustible cryogen. This paper gives an overview of the process and challenges of developing the payload and the results of its on-orbit performance.

Speaker: Dr Susan Breon (NASA Goddard Space Flight Center) -

10

C1Po1B-02 [13]: Integrated Refrigeration and Storage of LNG for Compositional Stability

Growing interest in liquefied natural gas (LNG) as a rocket fuel necessitates a greater technical understanding of the compositional changes due to preferential boil-off (or weathering) that occurs during long duration storage. The purity of methane in LNG can range from 90 to 98%, and is subject to preferential boil-off due to its low boiling point compared to other constituents despite the use of high-performance thermal insulation systems. Active heat extraction (i.e. refrigeration) is required to completely eliminate weathering. For future operational safety and reliability, and to better understand the quality and efficiency of the LNG as a cryofuel, a 400-liter Cryostat vessel was designed and constructed to measure the composition and temperatures of the LNG at a number of different liquid levels over long durations. The vessel is the centerpiece of a custom-designed lab-scale integrated refrigeration and storage (IRaS) system employing a G-M cryocooler capable of roughly 300 W of lift at 100 K. Instrumentation includes ten temperature sensors mounted on a vertical rake and five liquid sample tubes corresponding to five liquid levels. Two modes of operation are studied. The first is without refrigeration in order to determine a baseline in the change in composition, and to study stratification of the LNG. The second is performed with the cryocooler active to determine the operational parameters of the IRaS system for eliminating the weathering as well as stratification effects in the bulk liquid. The apparatus design and test method, as well as preliminary test results are presented in this paper. As a bonus in cost-saving and operational efficiency, the capability of the IRaS system to provide zero-loss capabilities such as zero boil-off (ZBO) keeping of the LNG and zero-loss filling/transfer operations are also discussed.

Speaker: Ms Laura Rose (NASA Kennedy Space Center) -

11

C1Po1B-03 [12]: Investigation on thermodynamic characteristics of cryogenic propellant slosh under varied gravity conditions

Acceleration variation in low-gravity environment could significantly affect propellant slosh as well as thermodynamic behaviors inside cryogenic tank of vehicle upper stage. To realize reliable space management of cryogenic propellant, liquid-gas interface movement and deformation as well as associated pressure evolution during the slosh process should be understood previously. In the present study, a 3-D computational fluid dynamics (CFD) model based on FLUENT software is introduced to assist the slosh analysis. The interface variations under different gravity changes are simulated, and interface oscillation damping features for both of smooth tank and baffle tank are compared and presented. The results show that the baffles indeed suppress interface slosh amplitude under relatively high gravity level, while the baffles effect is reduced under low-gravity condition. Moreover, when liquid level is higher than the top baffle position, the baffles could not suppress the slosh apparently. If the propellant tank experiences a sudden change from a high gravity to the microgravity level, extra contact between cold liquid and hot ullage-adjacent wall could bring about remarkable heat transfer and liquid evaporation, which further suppress the depressurization behavior in the beginning of ballistic period. In general, the present study could present the fluid behaviors and thermodynamic characteristics inside the cryogenic tank under slosh conditions, and the results could provide a reference for space propellant management and sequence setup.

Speaker: Mr Lei Wang -

12

C1Po1B-05 [10]: Estimation of heat dissipation on a rotating rotor over superconducting magnet bearing

The continuously rotational mechanism is one of key devices to holds a sapphire half wave plate (HWP) in a polarization modulator of a LiteBIRD satellite. Due to the system requirement, the HWP has to be kept at the cryogenic temperature while it is spinning. Thus, we employ a superconducting magnetic bearing (SMB) and AC synchronous motor, contactless rotational mechanism, to achieve the continuous rotation at the temperature range about 10 K. While we can minimize the frictional heat loss, an estimation of heat dissipation to this contactless rotor is important to predict how much the HWP temperature rises during its rotation. For an estimation of heat dissipation, we conduct two types of experiments in order to establish the thermal simulation model equivalent to the flight model in size. One is the experiment to estimate a thermal contact conductance s between the rotor and the cryogenic rotor holder mechanism. In this experiment, the rotor levitates still over a SMB with a heater and a thermometer mounted on the rotor, and thus we can apply a known Joule heat input. Then the rotor is grabbed through the cryogenic rotor holder mechanism. The other experiment is to monitor the difference of the temperature before and after the rotor rotation. We further monitor the transient temperature profiles of the holder mechanism after the rotor is gripped. The rotational time is related to the heat dissipation to the rotor because the heat dissipation is attributed to two kinds of energy losses: a magnetic hysteresis and induced eddy currents on metal parts of the rotor. Finally, we make a comparison between the thermal model and the experimental result and estimate the heat dissipation to the rotor during its spinning.

Speaker: Dr Teruhito Iida (ispace, inc.) -

13

C1Po1B-07 [09]: Numerical Analysis of Fluid Transients Induced by Valve Operation in Cryogenic Feed lines

Rapid change in fluid flow conditions, whether purposeful or accidental, may result in the generation of a pressure spike in the fluid flow system followed by oscillations of pressure which is known as the fluid transient/fluid hammer. The maximum amplitude of these oscillations may go beyond the safe operating limits of the system producing detrimental effects on pipelines, valves, pumps and other fluid network devices. Sometimes, the system pressure may also go below the vapor pressure of the fluid due to oscillating behavior of the wave which results in cavitation. Hence, it is essential to consider the effect of fluid transients for the correct design of the cryogenic propellant feed system of space launch vehicles which involves rapid closure and the opening of valves.

In the current work, a mathematical model is formulated using the Method of Characteristics to predict fluid transients occurring due to sudden closure and the opening of the valve in the cryogenic propellant feed system. Various unsteady friction models are incorporated in the mathematical model to study the effect of friction on dampening of the pressure wave. The applicability of the developed model is evaluated by comparing its predictions with the results available in the literature. It is observed from the current study that the first peak of the pressure oscillations can accurately be simulated with steady/quasi-steady friction, but the prediction of precise attenuation of pressure wave requires the inclusion of unsteady friction term.

Speaker: Arpit Mishra (Indian Institute of Technology (IIT), Kharagpur, India) -

14

C1Po1B-08 [08]: Experimental study on effect of non-uniform heat flux on self-pressurization and thermal stratification in a ground cryogenic tank

Simulations on self-pressurization and thermal stratification in cryogenic propellant storage tanks have been widely conducted in the literature. However, for the applications on orbit, the heat flux entering the tank could be non-uniform as the solar radiation angle varies, which may result in deviation of the behavior of pressurization and thermal stratification from regular conditions. That is, the knowledge on uniform heat load situations may not be applicable to practical ones. Moreover, few experimental studies on the non-uniform heating effect are available in the literature. In the present study, a ground experimental system has been established to investigate the self-pressurization and thermal stratification behaviors of liquid nitrogen with various fill-level under non-uniform heat leakage conditions. The comparative heat flux application modes include liquid-wetted-surface heating only, semi-liquid-wetted-surface heating, ullage-wall-surface heating only, semi-ullage-wall-surface heating, semi-liquid-semi-vapor surface heating, and all-liquid-vapor- surface heating. The fill-level of liquid nitrogen ranges from 30% to 90% for each mode. The pressurization rates and the temperature profiles within the liquid and ullage are both recorded and compared. Mechanism of the effects are discussed in perspective of cryogenic fluid convection.

Speaker: Mr X.J Qin (Institute of Refrigeration and Cryogenics, Shanghai Jiao Tong University) -

15

C1Po1B-09 [07]: CFD Analysis of Vortex Tube with Two-phase Air at Cryogenic Temperature

Ranque Hilsch vortex tube is commonly used with compressed air at atmospheric temperature for refrigeration purpose in various industrial applications. Literature shows that vortex tube can also be used as a potential device to separate compressed partially condensed air at cryogenic temperature into its main constituents – oxygen and nitrogen. When compressed partially condensed air is used as the working fluid, both energy separation and phase separation occur in the vortex tube. Due to turbulent mass transfer between the liquid phase and the vapor phase of air inside the tube, oxygen rich fluid stream comes out from the hot outlet and nitrogen rich fluid stream comes out from the cold outlet of vortex tube. Cryogenic vortex tube can be a potential device for use in an in-flight air collection and enrichment system of air breathing propulsion. However, literature on the CFD analysis of vortex tube with two-phase air flow at cryogenic temperature is very limited.

In this work, CFD simulation is conducted using the CFD software FLUENT to investigate energy separation and phase separation in vortex tube with partially condensed air at cryogenic temperature using the Eulerian multiphase model. Flow parameters inside the vortex tube operating with two-phase air are investigated and compared with those obtained for single phase vortex tube flow. Temperature separation with two-phase air is found to be less than that with the gaseous air. A thin layer of liquid is observed near the wall of the vortex tube in case of two-phase flow indicating phase separation in the vortex tube. Liquid mass fraction at the hot outlet is seen to be higher than that at the inlet. This indicates to oxygen enrichment of air at the hot outlet, because oxygen concentration is higher in the warmer liquid phase due to its lower volatility than nitrogen. Flow through the cold outlet is found to be predominantly gaseous with negligible liquid mass fraction, which indicates to nitrogen rich flow through the cold outlet.

Speaker: Prof. Tanmay Dutta (IIT (ISM) Dhanbad) -

16

C1Po1B-10 [06]: A Model Based Systems Engineering Approach to Achieve Zero Boil-off on A Nuclear Thermal Propulsion Spacecraft

Aerojet Rocketdyne’s 2033 Fast Conjunction Vehicle Concept to get to Mars is split into five segments: Deep Space Habitat, Inline Stages 1-3 and Core Stage. The three Inline Stages are propellant tanks carrying 19,205kg of liquid hydrogen (LH2). The Core Stage contains a smaller propellant tank of 14,084kg of LH2, a radiation attenuator and three nuclear thermal rocket engines. Each individual segment requires its own SLS rocket launch and will be launched every 180 days. Each segment will orbit around the moon—Near Rectilinear Halo Orbit (NRHO). NASA chose NRHO based on its low orbital stationkeeping and low thermal influence. The Inline Stage 1 is the first LH2-containing segment to reach NRHO with a loiter period of 905 days. Heat loads are of critical importance when storing LH2 due to its low boiling point. Venting the boiled LH2 is not an option for a mission of this length, which is why cryogenic fluid management (CFM) systems of passive and active cooling techniques need to work together to ensure zero boil-off. Several CFM systems will be simulated with one particular configuration involving lightweight, highly effective sun shades. Sun shades are deployable, radiation reflective shields that intercept incoming thermal radiation. Multiple sun shades can be stacked together and angled to allow thermal radiation between shields to reflect outward to space. A 2016 study showed that a two-stage cryocooler requires less mass and energy than a single-stage for large tanks due to the increase in heat load. By implementing one to many sun shades in-between the spacecraft and the sun, perhaps a single stage cryocooler configuration would be more advantageous—shown in the same 2016 study when looking at small tanks. Software tools such as Systems Modeling Language, MATLAB, Systems Tool Kit, and Model Center collaborate together to resolve this hypothesis.

Speaker: Mr Justin Conner (The University of Alabama in Huntsville)

-

9

-

C1Po1C - Stirling and VM Coolers Level 6, Cryo Expo Exhibit Hall

Level 6, Cryo Expo Exhibit Hall

Conveners: Ian McKinley (Jet Propulsion Laboratory), Jennifer Marquardt (Ball)-

17

C1Po1C-01 [05]: Development of a kW-class Stirling cryocooler for liquefaction of natural gas

Our research group has developed a kW-class Stirling cryocooler. The Stirling cryocooler adopts a ‘gamma-type’ configuration operated with a linear compressor. The cold-end of the Stirling cryocooler is equipped with a heat exchanger that can accept and eventually liquefy natural gas (NG). The liquefied natural gas (LNG) is stored in an auxiliary reservoir. In this research paper, the experiments as a proof of concept has been carried out. The Stirling cryocooler has been sorely tested prior to adopting the heat exchanger as the aforementioned above. It has been confirmed that the Stirling cryocooler can exert over 1 kW cooling capacity at 110 K cold-end temperature with 9 kW compressor input. This research paper mainly focuses on (1) relevant technical issues during the cooler development process and (2) demonstrating the liquefaction of argon gas (instead of using NG for the sake of safety regulation). The system presented in this paper, therefore, can be a good candidate for a small-scale liquefier does not require oil-involved maintenance.

Speaker: Dr Jiho Park (Korea Institute of Machinery and Materials) -

18

C1Po1C-02 [04]: Wide temperature range test of high capacity Stirling cryocooler

This paper describes the cooling performance test of a free piston Stirling cryocooler accompanied by a double acting linear compressor. Although, the aforementioned Stirling cryocooler had originally been subjected to 77 K applications, i.e. liquid nitrogen (LN2), in this research, we have tried to figure out the cooling performance of the Stirling cryocooler operating above-110 K temperature range. The relevant targets are as the follows, i.e. high temperature superconducting (HTS), liquid natural gas (LNG) re-liquefaction and industrial ultra-low freezer applications. During the experiments, the instantaneous pressures, displacement of the piston and the displacer, current and voltage have been acquired as the cold-end temperature varied from 110 K to 190 K. The Stirling cryocooler has recorded the Carnot COP to be 25%, 27%, 28% and 29% at the cold-end temperatures of 110 K, 120 K, 150 K and 190 K, respectively. In this research paper, all the physical variables will extensively be analyzed by a ‘dynamic model’ and the relevant operational issues will also be discussed.

Speaker: Dr Junseok Ko (Korea Institute of Machinery & Materials) -

19

C1Po1C-03 [03]: The Study on High Efficiency and Low Vibration Flexure Bearing Stirling Cryocooler

In this paper, a high efficiency and low vibration stirling cryocooler has been designed and manufactured. The high efficiency compressor implementing the technology of dual opposed moving magnet motor and flexure bearing has been optimized to drive pneumatically a stirling cold finger also implementing flexure bearing technology. Through theoretical study and experimental study, the cryocooler can reach performance of 3W/80K under 60 WAC of electrical power. The vibration of compressor is suppressed by reducing the weights of moving-masses and controlling the process of assembling. The vibration suppression of the cold finger is implemented in terms of a mass-spring passive balancer. The vibrations of compressor and the cold finger could be decreased to below 5.6 mg and 1.9 mg respectively under the above solutions.

Speaker: Mr Chuanlin Yin -

20

C1Po1C-04 [02]: Research progress of the Vuilleumier-type cryocooler working at liquid helium temperature and its further application prospect

The Vuilleumier (VM) cycler was first invented in 1908 and the Vuilleumier-type (VM-type) cryocooler has been developed over 100 years up to now. The VM-type cryocooler is driven by a thermal compressor and it inherits the advantage of compactness and high theoretical efficiency from the traditional Stirling-type cryocooler. It has been a current hotspot in regenerative mechanical cryocooler because the relative studies have proved its great potential to work at liquid helium temperature. In this paper, the research progress of the 4K VM-type cryocooler was showed. The detailed comparison in performance and working pattern between three different types of 4K VM-type cryocooler including VM displacer-type cryocooler, VM hybrid pulse tube cryocooler and VM-type pulse tube cryocooler is carried out. The further application prospect of the 4K VM-type cryocooler has been presented.

Speaker: Dr Liubiao Chen (CAS Key Laboratory of Cryogenics, Technical Institute of Physics and Chemistry, Beijing, 100049, China) -

21

C1Po1C-05 [01]: Numerical investigation on geometry's influence in double stage Vuilleumier type pulse tube cryocooler (VM-DPTC)

The double stage Vuilleumier type pulse tube cryocooler (VM-DPTC) is a novel kind of 4K-class pulse tube cryocooler driven by thermal compressor. Besides its compact size and low-frequency working pattern eliminating the moving parts in cryogenic temperature (<77K) will improve the working stability and reduce the inherited losses. To design a proper 4K double stage pulse tube cryocooler under a certain thermal compressor, a numerical model based on Sage 10 software is established. The geometry of the pulse tube cryocooler especially the influence of different combination of two stage's length on the no-load temperature and cooling power at 4.2K are studied. The numerical results shows that the second stage length should be longer than the first stage length to prevent the better performance of the VM-DPTC.

Speaker: Dr Liubiao Chen (CAS Key Laboratory of Cryogenics, Technical Institute of Physics and Chemistry, Beijing, 100049, China)

-

17

-

C1Po1D - Cryogen Technology Level 6, Cryo Expo Exhibit Hall

Level 6, Cryo Expo Exhibit Hall

Conveners: Peter Bradley (NIST), Jonathan Demko (LeTourneau University)-

22

C1Po1D-01 [25]: Cryogenic Flux Capacitor for Advanced Molecular and Energy Storage Applications

Effective storage and transfer of fluid commodities such as oxygen, hydrogen, natural gas, nitrogen, argon, and others is a necessity in many industries and for hosts of different applications. Molecules are typically contained as low pressure, cryogenic liquids; or as high-pressure gases. Liquefied gasses afford high energy and volume densities, but require complex storage systems to limit boil-off losses, need constant settling in zero-gravity, and are not well suited for overly dynamic situations where the tank orientation can change suddenly. Most cryogenic liquid tanks are complex, nested configurations to increase thermal performance, making them large, massive, and difficult to be made into conformal shapes. Conversely, high pressure gas storage bottles are unaffected by orientation, and can be kept at room temperature; however, these vessels are heavy-walled to contain the high pressures, and the energy densities associated with gas storage are dramatically lower. These two options are typically traded depending on the system requirements, but few practical options exist that provide the benefits while limiting the downfalls. Alternatively, the Cryogenic Flux Capacitor (CFC) technology employs nano-porous aerogel composites to store, by physisorption processes, large quantities of fluid molecules in a molecular solid-state condition, at moderate pressures and cryogenic temperatures. By virtue of its design architecture, a CFC device can be “charged” and “discharged” quickly and on-demand according to operational requirements. Three CFC application areas are introduced: CFC-Fuel, CFC-Cool, and CFC-Life, corresponding to designs utilizing fuels such as hydrogen and methane; inert fluids such as nitrogen and argon for cooling power; and oxygen or breathing air for life support. Data for physisorption within different aerogel composites are presented in terms of both mass and volumetric parameters. For several prototype CFC modules, the charging and discharging performance test data using nitrogen at 77 K are described.

Speaker: Adam Swanger (NASA Kennedy Space Center) -

23

C1Po1D-02 [26]: Distillation Based CO2 Removal from Natural Gas for Small and Medium Sized Plant

The removal of excess CO2 from natural gas to levels as low as 50 ppm is essential for the safe and reliable operation of liquefied natural gas (LNG) transport and delivery systems. Current chemical purification techniques, which are suitable for large processing plants, might not be suitable for small or mid-size plants which are expected to operate in future LNG delivery networks. The feasibility of purification of natural gas (NG) from CO2 down to a concentration of 50 ppm by multi-stage distillation is studied. A three-column distillation system is proposed that can purify NG to lower than 50 ppm concentration of CO2, while avoiding CO2 freezeout. The columns include a 30-stage demethanizer, in which high purity methane is obtained in the distillate by separating the impurities from natural gas including CO2; a 50-stage extractive column where the azeotrope between CO2 and ethane is broken; and a 50-stage solvent recovery column that recovers a mixture of heavy hydrocarbons suitable for recycling as a solvent back into the extractive column. The proposed system avoids CO2 freezeout by utilizing a multi component feed of some heavier hydrocarbons added to natural gas; propane, butane and pentane additives are injected into stage 20 of the demthanizer column alongside the raw feed. Furthermore, arrangements are made to break the CO2-ethane azeotrope, which may occur in the bottoms stream of the demthanizer by administering a solvent stream in the extractive column. The proposed system can operate in a closed loop arrangement where the bottoms stream that leaves the recovery column can be recycled and injected into the extractive column for azeotrope prevention.

Speaker: Veera Manek (Georgia Institute of Technology) -

24

C1Po1D-03 [27]: Oxygen Separation in a Vortex Tube with Applied Magnetic Field

The large scale and efficiency of air separation units remain key barriers towards modular, distributed liquid oxygen systems. Identifying new physical separation mechanisms, or novel combinations of established methods, could enable the development of smaller, more modular air separation systems. In this paper we investigate the combination of centrifugal separation with paramagnetism of liquid oxygen in a vortex tube. The magnetic field is applied via externally mounted 1.5 T bar magnets along the length of the hot end of the vortex tube. Various calibrated air and argon-oxygen mixtures are tested. Inlet vortex tube fluid conditions are varied from 80-90 K and 303.4-337.8 kPa. Gas chromatography analysis on the calibrated air samples shows the magnetic field gradient on the vortex tube produced a 68% increase in oxygen separation compared to the non-magnetic trials. Comparisons are made to competing oxygen separation methods. The results indicate a potential to increase oxygen purity and yield in a more compact form factor.

Speaker: Ms Jordan Raymond (Washington State University) -

25

C1Po1D-05 [28]: Design of dewar supports through topology optimization

Dewars are used to store and transport cryogens like LNG, LN2, LOX, LHe etc. These comprise two vessels, one placed inside the other and held together either at the “neck” (input/output port) or by support systems, depending on the capacity, the mechanical loads on the vessel and the boil-off characteristic of the stored cryogen. Support system based dewars are more common for real-life and industrial applications. Design of the support system are based on the principles that are used for high temperature pressure vessels. On the other hand, support system to be used for cryogenic fluid storage should also address the heat inleak through the supports along with the imposed mechanical load and thermal contraction-expansion effects. Some safety factors are prescribed in the literature to address these concerns; however, the scientific basis of design strategies available in the open literature so as to give a more scientific basis of design. This would result in reduction in use of excessive dimensions or material thereby reducing the payload and the capital cost. Considerations of mechanical load and thermal heat inleak often lead to diametric conclusions in terms of the diameter/thickness of the support system, leading to pareto-optimal solution. Topology optimization (TO) is often used to design structures like bridges, vehicles, robotic arms etc. by a systematic and sequential removal of the mass of the material being used to fabricate the given structure while meeting the constraints in terms of load bearing capacity of the structure and heat inleak. This methodology may be followed to arrive at an optimized geometry for the support system when the designer is unsure of the initial shape to start working. In this work, TO has been tested with various thermal and mechanical boundary conditions to arrive at optimized support geometry.

Speaker: B Nitin (Cryogenic Engineering Centre, Indian Institute of Technology Kharagpur) -

26

C1Po1D-06 [29]: Numerical study on cryogenic carbon capture by desublimation

Carbon dioxide (CO$2$) is the main contributor to greenhouse gases (GHG). Cryogenic carbon capture is a potential alternative for systems with higher CO$2$ concentration. These methods do not involve the use of any chemicals (like solvents, adsorbents etc.) or supports (like membrane), so that the costs of raw materials and/or their regeneration are done away with. Desublimation is one of the cryogenic carbon capture methods involving the conversion of gaseous CO$2$ to solid CO$2$ /dry ice by cooling the feed gas mixture. Before the desublimation of CO$2$ , all the condensable components (like water, particulate matter etc.) are removed. The primary unit of a desublimation-based carbon capture system is the desublimator that should ensure not only efficient cooling of the CO$2$ -laden gas but also effective removal of desublimated CO$2$ (solid) from the system. Nitrogen vapor, liquid nitrogen, liquid methane, hydrocarbon based refrigerant blend etc. are some possible coolants. A few numerical studies on the desublimation-based carbon capture have been reported in the literature. However, all the studies are based on feed gas with low CO$2$ concentration (up to 20 mol%) and carried out at lab scale only. In this work, a one dimensional numerical model of carbon capture process is developed for better understanding of CO$2$ desublimation process, with feed gas with higher CO$2$ concentration (>20 mol%). The model contains a tube-in-tube parallel-flow heat exchanger in which the CO$2$ -laden feed gas and the coolant are passed through the inner-and outer-tube of the heat exchanger respectively. The presented model shows the effects of the various process variables such as temperature, velocity etc. on the efficacy of carbon capture by desublimation. A parametric study is carried out to know the significance of each process variables.

Speakers: Mr Amit Rajkonwar (Cryogenic Engineering Centre, Indian Institute of Technology Kharagpur), Prof. Pavitra Sandilya (Cryogenic Engineering Centre, Indian Institute of Technology Kharagpur)

-

22

-

C1Po1E - Large Scale Systems I Level 6, Cryo Expo Exhibit Hall

Level 6, Cryo Expo Exhibit Hall

Conveners: Benjamin Hansen (Fermilab), Grzegorz Tatkowski (Fermilab)-

27

C1Po1E-01 [30]: Helium management of ESS cryoplants with common safety relief header and recovery system

The European Spallation Source (ESS) is a neutron-scattering facility being built with extensive international collaboration in Lund, Sweden. Three cryogenic plants with a vast cryogenic distribution system meet the cooling requirements of the superconducting RF cavities in the accelerator (ACCP), the cold hydrogen moderators in the target (TMCP), a cryomodule test stand and the sample environments for neutron instruments (TICP). The first of the three plants, the TICP has been successfully installed, commissioned and acceptance tested in 2018 by Air Liquide Advanced Technologies. Meanwhile the other two cryoplants (ACCP and TMCP) are under commissioning and testing by Linde Kryotechnik AG. The cryoplants share common helium buffer tanks, safety relief headers and helium recovery system due to historical, economical and architectural reasons. The helium recovery strategy and system configuration will be described in the paper. Resulting challenges, risks and safety relevant events that happened during, especially parallel, commissioning activities will be presented. The measures implemented to mitigate major risk and lessons learned are addressed as well.

Speaker: Mr Philipp Arnold (European Spallation Source ERIC) -

28

C1Po1E-04 [31]: Cryogenic System for the 2nd KSTAR Neutral Beam Injector

Another neutral beam injector (NBI-2) was added for the KSTAR plasma experiments, recently. It requires a deuterium gas cryo-condensation system with the pumping speeds over one million liter/sec. For this purpose, many cryo-panels and a liquid helium cryogenic system were designed and constructed take into accounting the previous NBI. After the independent performance tests of the NBI-2, it was connected to the KTSAR tokamak and applied in the plasma experiments in 2018. Details of the development results including engineering design, construction, and operation will be reported in this paper and presentation.

Speaker: Dr Young-Ju Lee (National Fusion Research Institute) -

29

C1Po1E-05 [32]: Conceptual design of the CFETR cryogenic system

The “CFETR integration engineering design” project and the program to develop an “integrated research facility for key systems of fusion reactor” have been granted by China in 2017. For the CFETR cryogenic system, an engineering conceptual design will be accomplished in 2020. The cryogenic system heat load is being calculated basing on the updated parameters of CFETR: a major and minor radius of 7.2 and 2.2 m, a fusion power of 200 to 1500 MW, a toroidal field of 6.5 T and a plasma current of 10 to 14 MA. Special attention will be addressed to the heat loads of the magnet system consisted of both HTS and LTS superconductor, the tritium separation system, and the cryopumps working at atmospheric pressure due to the D-T reaction. After the average heat load is determined, the function breakdown analysis and operation mode analysis of the cryogenic system will be performed. Finally, a reference PFD design will be proposed.

Speaker: Dr XiaoGang Liu (ASIPP) -

30

C1Po1E-06 [33]: Cryogenic System Design for CiADS Accelerator

China Initiative Accelerator Driven System (CiADS) is a high-power nuclear waste processing research facility being built at huizhou, Guangdong, CHINA. CiADS consists of a 2.5 MW superconducting proton linac with energy of 500 MeV and 5 mA, a liquid lead bismuth eutectic (LBE) cooled fast reactor with 10 MW, and a granular flow target employed to coupling the accelerator and the sub-critical core. The superconducting part of the proton linac is about 300 meters long and contains 29 cryomodules cooled by super-fluid helium. In order to decrease head loss of 2K super-fluid helium, the cryomodule should contain one thermal radiation shield operating from 50 to 65 K to prevent thermal radiation. Additionally, 4.5-K gas helium is used to provide forced cooling to the fundamental power couplers for the 2K cavities of cryomodule. So, a helium cryogenic system is designed by IMP to supply different cooling power for cryomodules.

Speakers: Xiaofei Niu (CAS), xiaohong Guo (CAS) -

31

C1Po1E-08 [34]: Thermodynamic and cost-effectiveness analyses of chosen cooling loops for local production of saturated superfluid helium in large cryogenic systems

Large scientific facilities applying HeII technologies usually use the Joule-Thomson expansion for the final production of saturated superfluid helium at their cryomodules or magnet cryostats. Required cooling power is usually delivered by the flow of subcooled liquid helium flow at

4.5 K and 3 to 4 bar(a). Then, the 4.5 K helium is precooled in a heat exchanger and throttled to a sub-atmospheric pressure below 50 mbar(a) to produce superfluid helium. This final throttling goes along an isenthalpic line which leads to the zone of wet vapour at quality of 15.9%. The efficiency of this process can be strongly affected by additional heat loads in the distribution line leading to higher temperatures in the heat exchanger as well as in the inlet to the JT valve, which may result in significantly higher quality of the throttled helium. This imperfection can be partly decreased by using a local subcooler or by splitting the expansion process into two phases with an intermediate point around 1.3 bar(a). However, these solutions require additional components, such as phase separators with some instrumentation and another throttling valve.

The paper presents the comparative thermodynamic analysis of the three cooling loops in respect to the initial, intermediate and final thermodynamic states of helium. Potential savings due to thermodynamic efficiency improvements are verified against the capital costs for different operation times.Speakers: Jaroslaw Fydrych (European Spallation Source ESS AB), Dr Slawomir Pietrowicz (Wroclaw University of Technology)

-

27

-

C1Po1F - Superconducting Magnet Systems I Level 6, Cryo Expo Exhibit Hall

Level 6, Cryo Expo Exhibit Hall

Conveners: Sastry Pamidi (CAPS/FSU), Mr Zijia Zhao (Tufts University)-

32

C1Po1F-01 [35]: Thermal Analysis of a Superconducting Undulator Cryostat for the APS Upgrade

The Advanced Photon Source Upgrade includes four 4.8-m long superconducting undulator (SCU) cryostats, each containing two up to 1.9-m long planar undulator NbTi magnets. The cooling is provided by six cryocoolers arranged in three thermal circuits. The magnets are indirectly cooled with LHe penetrating through channels in the magnet cores. This 4-K circuit which also includes a LHe tank, is cooled by five 4-K cryocooler 2nd stages. A beam vacuum that is thermally isolated from the magnets, is cooled by one 10-K cryocooler 2nd stage. A thermal shield and warm parts of current leads are cooled by the 1st stages of all six cryocoolers. This paper presents an ANSYS-based thermal analysis of the new SCU cryostat including all thermal circuits. The bench marked thermal conductance between the cryocooler cold heads and the LHe tank are used in the calculations as well as the measured cryocooler load lines. The model predicts temperatures in the system, total 4-K heat loads and an excess cooling power for various operational modes of the undulator.

Speaker: Dr Yuko Shiroyanagi (Argonne National Laboratory) -

33

C1Po1F-02 [36]: A New Superconducting Undulator Cryostat for the APS Upgrade

The Advanced Photon Source (APS) is in the midst of a major facility upgrade consisting of a new electron storage ring (SR) and many new insertion devices (IDs) which will provide x-ray photon beams to a new suite of experimental end stations. Included among the new IDs are four 4.8-meter superconducting undulator (SCU) cryostats, each containing two 1.9-meter planar undulator magnets operating at 4.2 K in either an in-line or canted configuration. We describe a new, compact cryocooler-based cryostat design which supports the magnets and associated subsystems and also fits the space constraints of the SR ID straight sections. The design is an evolution of earlier single-magnet 2-meter cryostats, retaining some subsystem commonality while incorporating lessons learned and several features unique to the challenge of supporting two independently operable undulator magnets in a single device.

* Work supported by the U.S. Department of Energy, Office of Science under Contract No. DE-AC02-06CH11357.Speaker: Mr Ethan Anliker (ANL) -

34

C1Po1F-03 [37]: The design and analysis of a superconducting magnet system for high field MRI

A superconducting multi-coil magnet system has been designed, analyzed and optimized, serving as demonstrator for a high filed Magnetic Resonance Imaging (MRI). This work focuses on the design and optimization of superconducting magnet, cryogenic cooling and cryostat systems.

The NbTi magnet system with multi-coils design has been optimized by balancing magnet performance, stability and offered field quality, against material- and cooling cost. The zero boil-off liquid He-cooled and conduction cooling system operated at 4.2 K, are both designed, analyzed and compared. For the cryostat, the space from inner surface of magnet to the room temperature bore should be kept narrow to maintain optimal field amplitude and homogeneity. This leads to the challenge of reconciling the mechanical constraints imposed by the coil geometry with the thermal insulation requirements. A straightforward structural elements is designed but with a high heat in-leak, while a local reinforced structure is also proposed and analyzed to achieve same space with less heat leak but with some manufacture difficulties. Here, the optimized design of the magnet system and its analysis (e.g. magnetic field, mechanical stress, thermal budget, etc.) are presented.Speaker: Prof. Chao Zhou (Institute of Plasma Physics, Chinese Academy of Sciences, Hefei, Anhui, China ) -

35

C1Po1F-04 [38]: Design and fabrication of the conduction cooling unit for the YBCO magnet of 1 MW superconducting induction heater

The 1 MW HTS induction heater has developed for the non-ferrous metal industry where the HTS coil is used to generate a static magnetic field. The HTS magnet is made of YBCO conductor produced by Shanghai Superconductor, and the prospected operating temperature is about 25 K. The conduction-cooled HTS magnet consists of three solenoid coils wound with 18 km YBCO conductor. The inner and outer diameters of the YBCO magnet are Φ1960mm and Φ2009mm, respectively. The magnet system is cooled by two AL325 cryorefrigerators. According to the testing results at rated operation current of 130 A, the temperature of the HTS coils and the thermal shield are less than 20 K and 70 K, respectively, while are much better than the expected value.

Speaker: Dr Tao Ma (Beijing Jiaotong University) -

36

C1Po1F-05 [39]: Conceptual cooling design for 14T MRI superconducting magnet system

At present,Ultra-high field MRI system is considered the right way to explore the human brain because of the brain activity would be seen at a resolution of hundreds of micrometers. In 2017,the Chinese government launched an ambitious project to design and manufacture a 14T MRI system in object to neuroscience research in future.The superconducting magnets made of Nb3Sn superconductor and NbTi superconductor is designed to generate a homogeneous field level of 14 T with a warm bore of 900 mm.In order to ensure the magnet could be operated in safety and stability with a higher temperature margin, the superconducting magnet system include main coil made of Nb3Sn superconductor and shielding coils made of NbTi superconductor will be immersed and cooled by the sub-cooled helium.In this paper,the concept design of the low-temperature structural and the cryogenic system will be introduced.

Speaker: Qiang Wang Hao -

37

C1Po1F-07 [40]: The Effect of the Material in a well-coupled shorted Secondary on Quench Protection of an Insulated ReBCO Tape Solenoid Magnet that is Quench Protected by discharging the Magnet across a Constant Voltage Resistor

Studies suggest that an insulated ReBCO tape solenoid coil that is well-coupled inductively to shorted secondary can effectively be quench protected by discharging the coil across a constant voltage resistor. The discharge voltage across the constant voltage resistor is much lower than it would be for a constant resistance resistor that is used to achieve the same final quench temperature with or without a shorted secondary. How this quench protection works, depends on the constant voltage resistor characteristics, the properties of the shorted secondary circuit material and the amount of the material in the circuit. A previous paper suggests that the RRR shorted secondary circuit material is not important, which means that aluminum can be used in the secondary circuit and structural aluminum can support both the coil and the secondary circuit when that aluminum is on the outside of a solenoidal coil.

Speaker: Dr Michael Green (Lawrence Berkeley Laboratory) -

38

C1Po1F-09 [42]: The Thermo-Electric Design of the Electric Current Feeders of the HL-LHC Triplet Magnets

The HL-LHC Project currently undertaken by CERN that provides an upgrade to the existing LHC accelerator, is designed to increase the luminosity of the colliding particle bunches by a factor of at least five.

Part of this upgrade will require the replacement of the existing groups of three superconducting LHC triplet magnets situated on each side of the ATLAS and CMS detectors with similar groups of four higher field HL-LHC triplet magnets of a new design that exploit coils manufactured with cables in Nb3Sn superconducting alloy.

The HL-LHC triplet magnets require separate electric current feeders linking their cold masses to their cryostat vacuum vessels, thermo-electrically optimised and specifically designed to separately feed their quench protection, beam tuning and instrumentation systems with electric current.

The HL-LHC instrumentation feedthrough system is similar, though containing a larger cable inventory, to that mounted on existing cryo-magnets in the LHC accelerator whereas the quench protection and beam tuning systems, both present new requirements calling for a substantially different design approach.

The quench protection system requires a sinusoidal pulse at about 6Hz peaking at 3000 A and decaying exponentially to close to zero in about 2 seconds.

Beam tuning requires a 35A peak continuous sinusoidal input with a period varying between 60 and 30 s and must withstand occasional simultaneous single current pulses rising to 4000A and decaying to zero in about 0.5 seconds.

Installed in a highly activated zone of the LHC, all three systems, designed to be maintenance-free, consequently exploit only natural heat convection to prevent the formation of condensation at their warm ends.

This paper describes the functional design and thermo-electrical optimisation achieved for each of these current feeder systems.Speaker: Mr Florian Pasdeloup (CERN) -

39

C1Po1F-10 [43]: Thermal engineering of optical mirrors for use at cryogenic temperature inside a LHC cryostat

In the frame of the HL-LHC project, innovative technical solutions are sought to measure accurately the position of the magnet cold mass inside the cryostat. To this end, a system based on laser-interferometry is being designed to monitor the displacement of the cold mass through dedicated openings in the new HL-LHC cryostats.

In order to test such a system on a full-scale setup in representative operating conditions, a LHC dipole cryostat was modified to integrate the system optical lines of sight and the reflective mirrors were mounted onto the magnet helium vessel.

Upon the first cool down of the magnet helium vessel to 80K, severe ice-like condensation started forming on the reflective surface of the mirrors hence making the system unusable at cold. This was attributed to the condensation of the residual gas remaining in the cryostat insulation vacuum on the mirror surface. In this configuration the mirrors acted as local “cold spots” since they were purposefully sticking out of the multi-layer insulation (MLI) that is otherwise covering the magnet helium vessel.

In order to cope with this condensation issue, a dedicated study was carried out to design and manufacture a passive temperature regulation system based on a thermal insulating support and a thermal radiation intercept in order to keep the mirrors just above the expected freezing temperature in operational conditions.

This paper details the thermal engineering study leading to the design of the insulated mirrors and presents the technical solution retained as well as the latest test results.Speaker: Florian Pasdeloup (CERN)

-

32

-

M1Or1A - Focus Series A: REBCO Coated Conductors I Level 6, Room 14

Level 6, Room 14

Conveners: Markus Bauer (THEVA Dünnschichttechnik GmbH), Venkat Selvamanickam (University of Houston)-

40

M1Or1A-01 [Invited]: Recent progress in SuNAM’s coated conductor development

SuNAM’s RCE-DR (Reactive Co-Evaporation by Deposition and Reaction) process has been proved to be a high-throughput, cost-effective production method for the deposition of superconducting layer for coated conductor(CC). We showed that higher than 1 kA/cm-width critical current tape can be produced routinely, though our standard product comes with 700~800 A/12 mm-width only because we care for overall process optimization.

We improved in-field critical current of our tapes by i)optimization of intrinsic pinning of RE2O3 by the control of starting composition and/or process temperature and gas pressure, ii) mixture of RE materials such as Gd, Y, Sm, etc. The results are very promising in mid-field of upto 10 T and our current effort is on extending to a higher field.

In addition to our catalog of high-field magnets of 26.4 T(highest field achieved with HTS at that time) and 18 T(the first commercial high-field HTS magnet to our knowledge), we succeeded in developing highly homogeneous 9.4-T mange for 400 MHz NMR.

SuNAM’s recent activities, in addition to the above mentioned ones, will be presented.

Speaker: Dr Seung-Hyun Moon (SuNAM Co., Ltd.) -

41

M1Or1A-02 [Invited]: Development of BMO Doped REBCO Coated Conductors with Homogenous In-field Properties by Productive Hot-Wall PLD Process

In order to overcome the narrower deposition windows and less longitudinal homogeneity for high in-field performance BaMO3 (M : Zr or Hf etc.) doped REBCO film, we applied hot-wall type pulsed-laser-deposition (PLD), which realized quite homogeneous crystalline growth conditions for REBCO by furnace-like substrate heating without spoiling productive throughput.

We studied growth condition dependence of BMO nano-rod structure, and Jc (B, theta, T) properties. Clear growth rate dependence were observed for c-axis correlated flux pinning properties and the shape and densities of nano-rod structure which should be affected by adatom migration durations. Though the minimum Jc (theta) of those samples were not so different at the temperature over ~30 K, the difference increased gradually at lower temperatures. The minimum Jc (theta) increased up to four times bigger for low growth rate samples of 5-7 nm/sec, as two-times for high-growth rate samples of 20-50 nm/sec, than non-doped REBCO films, at 4.2 K, 15 T.

The temperature and field dependent scaling properties were also studied for pinning force densities at the field configuration parallel to c-axis. The results indicated that strong c-axis correlated pinning could be only observed in low growth rate samples, where high-growth rate samples of >20 nm/sec had quite simple scaling properties similar to non-doped samples.

We finally optimized the deposition parameters so that they contribute to both good productivity with high growth rate of 20-50 nm/sec, and less angular dependent and large enough in-field Ic properties which agree to Jc-B scaling law in wide temperature and field range. Production samples of 300-600 m long were routinely fabricated and test samples of 1 km long class also produced with good Ic uniformity comparable to non-doped REBCO wires. Ic uniformity was examined by scanning Hall probe microscopy (RTR-SHPM), and also end-to-end transport measurement in magnetic fields, etc. A part of this work is based on results obtained from a project subsidized by the New Energy and Industrial Technology Development Organization (NEDO).Speaker: Dr Yasuhiro Iijima (Fujikura Ltd.) -

42

M1Or1A-03 [Invited]: Present Directions for 2G HTS Wire Development at SuperOx

Recently, in response to the growing demand on 2G HTS wire, both internal and external, the SuperOx group of companies has increased its production capacity, bringing it in 2018 to 120 km of 12 mm wide wire per year. Another incremental increase is planned in 2019.

As the fabrication technologies of 2G HTS wire have become more mature over the few last years, the key product development directions are focused now on better satisfying the demands of specific wire applications and addressing common issues, for instance, improving reproducibility and mechanical strength.

Key wire development directions at SuperOx are: (1) to increase the wire critical current at liquid nitrogen temperature in self-field for application in FCL and cables; the particular target is to go beyond the Ic of 800 A/12 mm at 77 K, and (2) to increase the engineering current density at low temperature in high magnetic field for application in magnets; the particular target is to go beyond the Je of 700 A/mm2 at 20 K, 20 T.

We adopt into production the approaches successfully demonstrated at lab-scale, such as: to increase the HTS layer thickness with minimum degradation of Jc, to modify the HTS layer composition for enhanced pinning, to use thinner substrate for higher Je, and to use laser slitting instead of mechanical slitting for better reproducibility and mechanical properties of narrow wire strips.

We will report the results of these activities and give examples of specific HTS device projects and associated wire requirements that drive the progress.

Acknowledgement: SuperOx acknowledges the support from Ministry of Science and Higher Education of the Russian Federation, Grant 075-11-2018-176.

Speakers: Dr Alexander Molodyk (SuperOx), Dr Alexey Mankevich (SuperOx)

-

40

-

C1Or1A - Aerospace Cryocoolers I Level 6, Room 26-27

Level 6, Room 26-27

Conveners: Franklin Miller (University of Wisconsin - Madison), Peter Shirron (NASA/GSFC)-

43

C1Or1A-01: Performance Characteristics Comparison of Major Types of Mechanical Cryocoolers for Aerospace Applications

The three major types of mechanical cryocoolers in aerospace applications, namely reverse-Brayton cryocoolers, Stirling/pulse tube cryocoolers and Joule-Thomson cryocoolers, have significantly different performance characteristics. Some of these differences are due to the nature of their thermodynamic cycles; others come from their drastically differences in mean operating pressures and pressure ratios. This paper first discusses the key control parameters affecting the sizes and mass of the compressors and heat exchanges in each type of cryocoolers; then compares the performance characteristics of these three types of cryocoolers in several cooling temperature ranges and cooling capacities of interest to the aerospace community; and finally summarizes the performance benefits and associated main applications of each type of cryocoolers.

Speaker: Weibo Chen (Jet Propulsion Lab) -

44

C1Or1A-02: Status of Lockheed Martin Microcryocooler Programs

There is an increasing need for compact, low-mass, long-life cryocoolers for Earth science, deep space, and astrophysics missions. Packaging a cryocooler within a CubeSat is challenging, and many deep space missions have extreme environmental conditions, such as exposure of “warm” hardware to cryogenic temperatures, and exposure to very high levels of radiation. Lockheed Martin’s microcryocooler has a mass of less than 500 grams and is currently the only long-life space cryocooler capable of being packaged within a 1U CubeSat.

This talk will describe the status of several microcryocooler programs at Lockheed Martin’s Advanced Technology Center in Palo Alto, California. LM integrated and tested a microcryocooler with a CubeSat instrument, which will be launched alongside the Orion spacecraft on the EM-1 launch vehicle, scheduled for launch in 2020. This CubeSat will take IR images of the moon during a flyby. LM is also building the cryocoolers for the Mapping Imaging Spectrometer for Europa (MISE), an instrument being built by the Jet Propulsion laboratory for the Europa Clipper Mission, and the flight program for this work has begun. LM has recently completed engineering model cryocoolers for a Gamma Ray Spectrometer being built by the Johns Hopkins University Applied Physics Laboratory for the Psyche asteroid mission, and the flight program is expected to begin prior to the 2019 CEC. LM successfully completed a Phase II SBIR with Iris Technology, building and delivering a microcryocooler capable of providing 0.3 W cooling at 35 K while rejecting heat at 150 K.

Speaker: Jeffrey Olson (Lockheed Martin Space) -

45

C1Or1A-03: Characterization Testing of Lockheed Martin Micro1-2 Cryocoolers for the Mapping Imaging Spectrometer for Europa

The Mapping Imaging Spectrometer for Europa (MISE) instrument on the Europa Clipper mission will use a Lockheed Martin “high power” Micro1-2 pulse tube cryocooler with a heat rejection temperature below 250 K. This paper describes the performance testing and results of Lockheed Martin Micro1-2 coolers optimized for these conditions. The thermal performance of two microcoolers was measured in vacuum for heat reject temperatures between 220 and 260 K for different helium fill pressures. The coolers were driven with input powers ranging from 5 to 40 W and drive frequency between 125 and 150 Hz. The optimal drive frequency was dependent on both input power and heat reject temperature. For all conditions measured, the heat flow from the compressor was between 54% and 58% of the total heat and the compressor temperature was between 4 K and 6 K warmer than the expander temperature. In addition, another Micro1-2 cooler optimized for 300 K environment was subjected to a life-test at cold reject temperatures spanning three times the expected life on the Europa mission. The cooler performance and helium leak rate did not change over this duration. Moreover, a burst test was performed on a unit of this model of cooler that did not have the internal components. Finally, the conversion efficiency of Iris Technologies Low Cost Control Electronics (LCCE-2) was measured while operating a Micro1-2 cooler over input powers of 5 W to 50 W. The conversion efficiency was independent of drive frequency.

Speaker: Ian McKinley (Jet Propulsion Laboratory) -

46

C1Or1A-04: Northrop Grumman Next Generation MiniCooler Plus Performance

Northrop Grumman Aerospace Systems (NGAS) has expanded its cryocooler product line with the introduction of the Mini Cooler Plus. The NGAS Mini Cooler Plus is a split cooler with a coaxial cold head connected through a transfer line to a vibrationally balanced back to back linear compressor. The mini compressor plus is designed for Space and non-Space applications. It is scaled from NGAS flight proven TRL9 family of compressors and contains non-wearing pistons suspended on flexure bearings. Designed for greater than 10 years of operation, the 2.6 Kg mini cooler plus can cool payloads at temperatures down to 45K while rejecting heat over a wide range of temperatures. This paper reports on the performance of NGAS mini cooler plus.

Speaker: Ladan Amouzegar Ashtiani -

47

C1Or1A-05: Thermal and Exported Vibration Characterization of Ricor K508N Cryocooler

The Ricor K508N is an upgraded version of the K508 that has extensive flight heritage. This paper reports performance and exported force results for the COTS K508N as well as a K508N filled to a higher fill pressure with a high frequency motor. A comparison is made between the results of the K508N coolers and the K508 to determine their suitability for cooling on CubeSat missions. In addition, exported force results for various vibration damping techniques are discussed. The thermal performance of the coolers was measured in vacuum for -40°C, 20°C and 57°C heat reject temperatures. The coolers were operated in open-loop and in closed-loop mode during thermal performance testing. The exported vibration levels of the coolers were measured on a dynamometer with and without vibration isolators.

Speaker: Mr Mason Mok (Jet Propulsion Laboratory) -

48

C1Or1A-06: Micro-Sized Cryocooler Controllers for Space

The explosion in SmallSat and CubeSat deployments has led to a need for miniaturized cooling solutions for sensors that require cooling. Since there are limited opportunities for miniaturization in the thermal mechanical unit (TMU) portion of the cryocooling system, much of the pressure to reduce size falls on the cryocooler control electronics (CCE). In the world of digital electronics, continuous size reduction is the expected norm, however, in the world of power electronics this is not the case. The number of components and their variety is greatly limited when selecting space grade electronics, typically resulting in designs that make space grade electronic solutions much larger than an equivalent circuit made of commercial grade electronics.

One way to reduce the size of the power components is to switch at a higher speed. The current generation CCE devices built by Iris Technology utilize MOSFET power transistors to perform power conversion. The characteristics of the power MOSFETs limit the switch rate to something on the order of 100 kHz, thus driving the energy storage requirements of the capacitors and inductors. If we could switch faster we reduce the required energy storage and thus the size of the inductors and capacitors.

One solution to the switching frequency problem is the use of Gallium Nitride (GaN) FETs which can be switched on the order of 1 MHz. GaN FETs are inherently radiation tolerant, however recently GaN FETs have become available with space grade packaging. The space grade packaging is available with an integral radiation hardened high/low side driver. This integrated part provides further size reduction to the electronics design.

Recently, high performance space grade microcontrollers have become available. These parts offer another integration opportunity, as the FPGA and ADC functions can be combined into a single smaller chip. Space grade GaN FETs when combined with the space grade microcontrollers provide an opportunity for significant reduction in the volume required for the CCE portion of a cryocooler system.Speaker: Kerry Frohling (Iris Technology)

-

43

-

C1Or1B - Large Scale Systems II Level 6, Room 24-25

Level 6, Room 24-25

Conveners: Shrikant Pattalwar (STFC Daresbury Laboratory, UK), Michael White (Fermilab)-

49

C1Or1B-01: The ESS Test and Instruments Cryoplant – First test results and operation experiences

The European Spallation Source (ESS) is a neutron-scattering facility being built with extensive international collaboration in Lund, Sweden. The world’s most powerful linear proton accelerator shoots protons against a rotating tungsten target where neutrons are knocked off (“spallate”) and are guided to the neutron instrument suites. Three cryogenic plants and a vast cryogenic distribution system serve the cooling needs of the superconducting RF cavities in the accelerator, the cold hydrogen moderators in the target, a cryomodule test stand and the sample environments for neutron instruments. The project’s demand of schedule and economic feasibility requires a high degree of parallel work for installation and commissioning of the cryogenic and auxiliary systems.

The first of the three plants, the Test and Instrumentation Cryoplant (TICP) has been installed, commissioned and acceptance tested in 2018 by Air Liquide Advanced Technologies. The plant consist not only of a standard compressor system and coldbox but also of a process vacuum system for 2K operation, internal and external helium purifiers, liquid helium tank, filling and boil of station and a helium recovery system. It is heavily integrated in the overall cryogenic installations at ESS. The paper describes some project challenges, acceptance test results and first operation experience. The current status of the ESS cryogenic system and lessons learned are addressed as well.Speaker: Mr Philipp Arnold (European Spallation Source ERIC) -

50

C1Or1B-02: Cryogenic operational experience from the LHC physics run2 (2015-2018 inclusive)

With end of year 2018 the LHC has completed its second physics run and started its second two-years long shut down period dedicated to planned consolidation, maintenance and upgrade activities. The run2 – four-year physics operation period started in spring 2015 – was used mainly for luminosity production but also to allow the optimization and adaptability of the cryogenic system capacity to compensate the generated operational static and dynamic heat loads. Several tests and qualifications were studied and applied to the configuration of the available equipment in order to reach and deeply understand the real operation limits. Dedicated improvements were implemented in the control system, especially in regards of handling the beam induced dynamic heat load during transitory and operational states as well as to compensate dynamic heat load related to secondaries in the Inner Triplet magnets, close to the interaction points of the ATLAS and CMS detectors. This paper will give a general overview of the LHC cryogenics operation with specific information on encountered operational difficulties and applied solutions on the system. Helium inventory management, including process use and leaks, as well as the system overall availability indicators will be presented.

Speaker: Laurent Delprat (CERN) -

51

C1Or1B-03: Cryogenic system design for the electron-ion collider at Brookhaven National Laboratory

Brookhaven National Laboratory operates the only functioning collider in the United States – the Relativistic Heavy Ion Collider (RHIC). The electron-ion collider (eRHIC) at Brookhaven National Laboratory (BNL) is a proposed large scale upgrade to the existing RHIC facility and is currently in its R&D phase. The new machine involves the use of superconducting technology for accelerating and steering beams of charged particles. This study focuses on the design of local cryogenic system that will supply cooling to these SRF cryomodules located at interaction point (IP) 10. Several system configuration options are given depending on the energy level at which the new collider operates, and hence the level of SRF cryogenic loads. In addition to this, the study also explores challenges in integrating all these brand-new subsystems to the existing RHIC cryogenic system.

Speaker: Dhananjay Ravikumar (Brookhaven National Laboratory) -

52

C1Or1B-04: Application of Sub-cooled Superfluid Helium for Cavity Cooling at linac-based Free Electron Lasers, Energy Recovery and Proton Linacs

Compactness of linear accelerator is significant factor in achieving short construction times, low infrastructure and operation costs, and is considered as one of key parameters for the next accelerator generation. Operation of XFEL and other accelerators shows the possible limitations on present technologies related to the RF power operation inside the cryomodules. The next development steps could be either further increase of Q0 factor of the cavities or other cooling methods. In the present paper, modification of the superfluid helium bath cooling scheme is presented. This will allow increasing the RF power by factor two or more. Application of the sub-cooling scheme for SNS/ESS/CEBAF-types cryomodules is considered. In order to operate at higher RF power levels, improvements of cooling methods for a fundamental power coupler are also discussed.

Speaker: Dr Sergiy Putselyk (FHR) -

53

C1Or1B-06: Cryogenic management of the LHC Run 2 dynamic heat loads