MT26 Abstracts, Timetable and Presentations

Hyatt Regency Hotel Vancouver

The detailed Technical Program can be accessed via the Timetable Views on the left.

Late submissions are no longer accepted except for the extreme circumstance of presenting last minute, ground-breaking research. In such cases, please email your abstract to mt@centennialconferences.com and be sure to include the appropriate submission category. Abstracts will be sent to the Program Committee for possible consideration at the committee’s discretion.

Anyone presenting at and/or attending the conference must be a registered participant. Registration information will be made available at the MT26 website.

If you have a presentation, you must first login via the upper right corner; then click on “My Contributions” below “Presentation(s)”.

ALL PRESENTERS must upload an electronic copy of their talk in PDF or PPT(X) format prior to their presentation at the scheduled MT26 session. By participating at MT26 and submitting your presentation, you implicitly agree to publish the content of your presentation on the public Indico site.

Presenters of oral talks must also submit their presentation file to the Speaker Preparation Room (Dover/Tennyson Room) one (1) day prior to their scheduled presentation.

Detailed presentation guidelines are available via the left side navigation of this site.

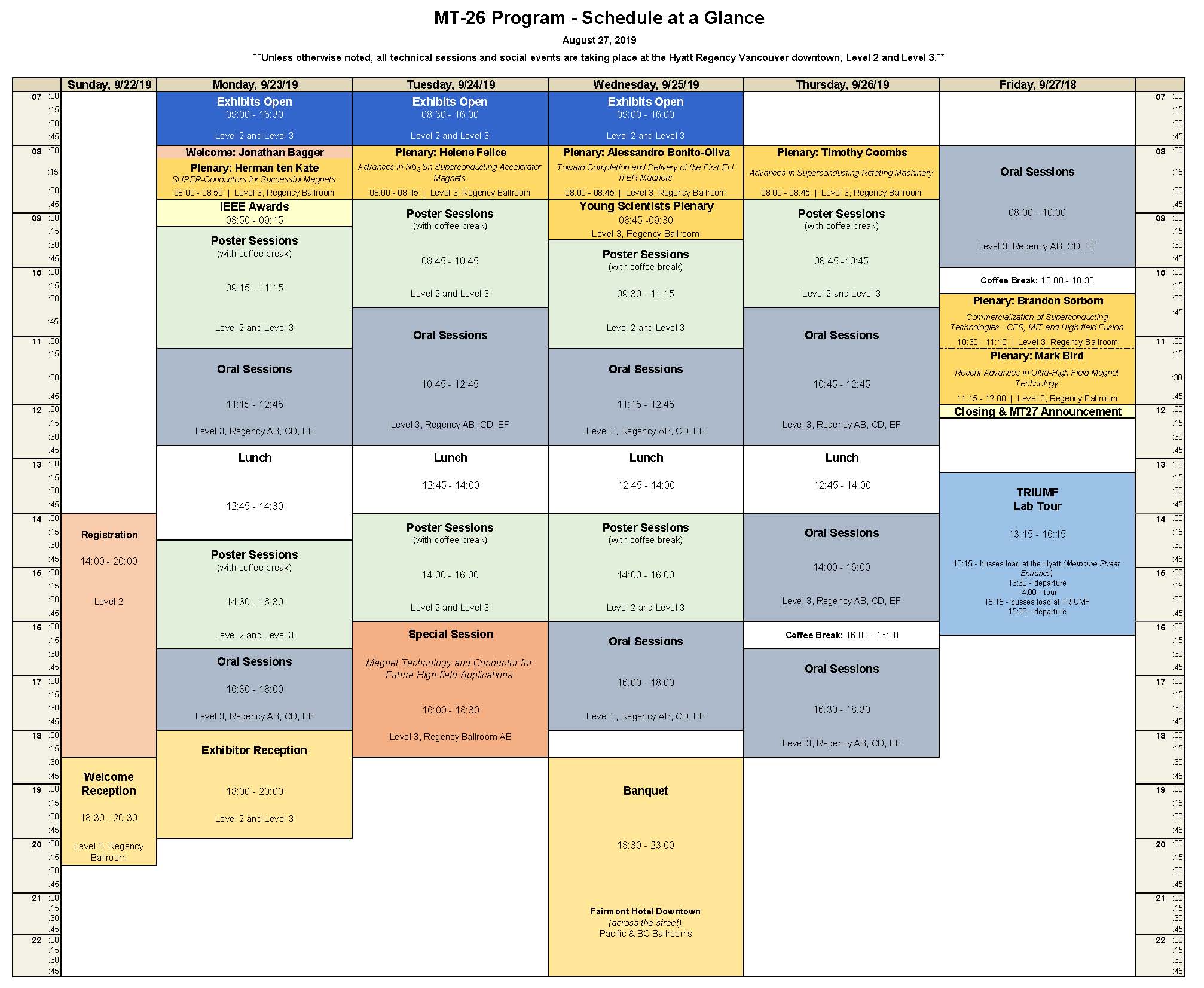

Click on the image below to download the Schedule at a Glance in PDF format.

All other conference information can be found at mt26.triumf.ca.

-

-

14:00

Registration Open Level 3, Regency Ballroom

Level 3, Regency Ballroom

-

18:30

Welcome Reception Level 3, Regency Ballroom

Level 3, Regency Ballroom

-

14:00

-

-

07:50

Registration Open (7:00 AM - 6:30 PM)

-

07:55

Exhibits Open (9:00 AM - 4:30 PM) Level 2 and Level 3

Level 2 and Level 3

For a list of Exhibitors, please visit: https://mt26.triumf.ca/#exhibitors.

-

08:00

MT26 Opening Level 3, Regency Ballroom

Level 3, Regency Ballroom

-

Plenary: Herman ten Kate (CERN) Regency Ballroom

Regency Ballroom

Convener: Prof. Lance Cooley (ASC/NHMFL/FSU)-

1

Mo-Mo-PL1-01: SUPER-Conductors for Successful Magnets

Defining what a successful SUPER-conductor for a magnet is, isn’t easy. It is often underestimated to what extend the type of magnet and its application are strongly determining the conductor requirements. Whether it is a one-off magnet where cost is not an issue, a quasi-commercial small series, or a long-term commercial production of magnets, is crucially influencing the conductor choice. The technical and economic considerations for a single high-end magnet in a satellite or for an insert in a high-field facility are very different from those for a few hundred or thousands of magnets for particle accelerators or ultimately the long-term series production of MRI magnets.

In textbooks, we find long tables with superconducting materials ever discovered, but when it comes to those for practical use in magnets, only a few remain. Yet another hurdle we encounter when attempting to use these NbTi, Nb3Sn, MgB2, BSCCO and ReBCO wires in high-current multi-strand cables and often mechanically reinforced conductors. They have to survive the enormous Lorentz force and thermal-electro-magnetic infestation present in large-scale magnets and guarantee degradation free and reliable operation for some 20 to 30 years.

The requirements for successful SUPER-conductors will be reviewed and a few striking examples, where naive initial designs had to be corrected, will be presented. Long-term research and development to learn, understand and improve not only bare transport properties of conductors but also their thermal-mechanical behavior are required for magnets to be successful.Speaker: Herman Ten Kate (CERN)

-

1

-

08:50

IEEE Awards Presentations

-

09:15

Coffee Break (during Poster Sessions)

-

Mon-Mo-Po1.01 - Quench Protection and Detection Systems I Level 2 Posters 1

Level 2 Posters 1

Conveners: Konstantinos Bouloukakis (Victoria University of Wellington), Maxim Marchevsky (LBNL)-

2

Mon-Mo-Po1.01-01 [1]: Presentation withdrawn

-

3

Mon-Mo-Po1.01-02 [2]: Design and Evaluation of a Controllable Contact Resistance for Meter-Class REBCO No-Insulation Pancake Coils

We focusing on investigating the protection of meter-class REBCO no-insulation (NI) coils applied in next generation high-field magnetic resonance imaging scanners. In order to address the issue of controllable contact resistance, we proposed a method is based on an external variable resistance, which is paralleled with an NI coil to realize the controllable contact resistance. It can maintain the temperature increase of the coil in the safety range during a charging and discharging by the efficient leading-out the electromagnetic energy. To certify the feasibility of this method, in this study, a numerical analysis was conducted of a partial element equivalent circuit along with a thermal analysis of a simple equivalent circuit model to investigate the effective range of variable resistor to realize the protection method for the meter-class NI coil. Based on the results, we discussed the feasibility of the inhibitory effect of variable resistor on the temperature increase of meter-class NI coil and the energy dissipation rate during a sudden discharging.

Speaker: Prof. Tao Wang (Nanjing University of Science and Technology) -

4

Mon-Mo-Po1.01-04 [3]: Performance of the Large Hadron Collider’s Cryogenic Bypass Diodes over the First Two Physics Runs, Future Projects and Perspectives

Cryogenic bypass diodes have been installed in all superconducting dipole magnets (1232) and all main superconducting quadrupole magnets (392) of the Large Hadron Collider (LHC) at CERN, and operated during the physics runs since 2009. The by-pass diodes are a fundamental ingredient of the quench protection system for those main dipoles and quadrupoles magnets. Diodes are located inside the magnet cryostats, operating in superfluid helium and exposed to ionizing radiation. The connection between the superconducting magnet and the bypass diode is made through a mechanically clamping system and copper bus bars. Since their first installation, all LHC diodes have undergone at least one full thermal cycle (from 1.9 K to room temperature and back to superfluid helium temperature).

The evolution of electrical parameters as well as improvements and modifications made over a period of 10 years are reviewed under a critical eye.

The maximum estimated dose accumulated for one single diode is today of the order of 500 Gy. A test setup has been developed to qualify diodes for higher neutron fluences and integrated doses than they were initially. The setup was installed at CERN in a radiation test facility and diodes irradiated at cryogenic temperatures over 2018. The qualification process has allowed to identify three candidates that could be used for the new High-Luminosity LHC circuits. This paper will also report on the behaviour and performance of the diodes that have been measured.

With CERN preparing for LHC’s High Luminosity era, the long-term strategy for cold diodes will be presented, based on the overall results and experience gathered so far.Speaker: Giorgio D'Angelo (CERN) -

5

Mon-Mo-Po1.01-05 [4]: Quench protection method using current of magnetically coupled secondary coil for fast current reduction of superconducting magnet

In general, superconducting magnets operate at high currents, and excessive joule heating due to high currents can damage the magnet when quench occurs. Therefore, a quench protection system that can reduce the magnet current quickly is required when the normal zone occurs in the magnet. For this reason, several quench protection methods are being developed to rapidly reduce the current. In this paper, we present a new quench protection method that rapidly reduces current in a superconducting magnet by injecting current into a magnetically coupled secondary coil. The proposed system is magnetically coupled without direct connection to the magnet and is used in conjunction with a protection method using a conventional dump resistor to help reduce the current quickly. The performance of this system was verified using a small scale high temperature superconducting test coil.

Speaker: Yojong Choi (Yonsei University, Seoul, Korea) -

6

Mon-Mo-Po1.01-06 [5]: Voltage Signal rate change of Quench Detection by Real-Time Least squares for HTS Tape and Coil

The quenching of superconducting magnets is one of the key issues affecting the safe and stable operation of superconducting devices. The effect of Magnetic flux jump and electro-magnetic stress leads to local critical current drop, continuous accumulation of heat of joint resistance, failure of refrigeration equipment or other auxiliary equipment, etc. These effects may cause quenching of the superconducting magnet. When the superconducting magnet is quenching, it will cause the point of overheating. When the quenching is continued, the locali-zation will continue to heat up. Therefore, the establishment of the automatic quench protec-tion system and the correction of the quenching judgment are important for the long-term sta-ble operation of the superconducting device. In poor electromagnetic environment, quench detection based on electrometric method is easily interfered by noise and severely disrupted quench signal may cause wrong quench determination and malfunction of quench pro-tection, thereby resulting in unnecessary loss. Because of the noise cannot be completely eliminated, in order to effectively judge the quench and reduce the malfunction of the annihilation detec-tion, a real-time least squares method is proposed.

The overcurrent experiment shows that the real-time least squares method can effectively judge the point of quench.Speaker: Jie Chen -

7

Mon-Mo-Po1.01-07 [6]: Optimal Design and Performance Evaluation of Quench Protection System using Dual-capacitor Switching with Various Design Parameters for scale-up Test coil

Recently, a new quench protection system using capacitor and switches has been announced to rapidly extract energy from high temperature superconducting (HTS) magnets. When a quench occurs, the quench protection system activates four MOSFET switches in sequence, and the energy stored in the magnet is extracted through an external resistor through a capacitor. In previous studies, the system was implemented for the protection of small-scale magnets, and the feasibility of the system was experimentally verified. The experimental results show that the energy extraction of the magnet is faster than the quench protection system using a conventional dump resistor. However, since proposed system is sensitive to capacitance, inductance, and four resistors, it is necessary to optimize design variables for various magnet systems. However, since the system is sensitive to capacitance, inductance, and four resistances, it is necessary to analyze and optimize the design parameters for various magnet systems. In this paper, the effect of each design variable on the protection performance is analyzed and a method for optimal design is presented. We also evaluated the performance by applying a design optimized for the scale-up test coil.

Speaker: Yojong Choi (Yonsei University, Seoul, Korea) -

8

Mon-Mo-Po1.01-08 [7]: Quench Protection of Multi-coil Low Temperature Superconducting Systems

Quench protection is critical for superconducting systems, especially those containing enough energy to damage the system during quench. We propose a new quench protection approach for multi-coil low temperature superconducting (LTS) systems that minimizes the number of protection components that must be activated during quench. In this approach, the electrically (and probably also inductively) coupled coils are electrically connected in these possible ways: all in parallel; several parallel-connected groups, with each group consisting of several series connected coils; several series-connected groups, with each group consisting of several coils in parallel. If one of the parallel-connected coils or groups quenches, current in this coil or group decreases while current in the other parallel-connected coils or groups tries to increase to keep total current flow in the circuit the same, and this tendency will be affected by the nature of the inductive coupling among the coils. If during this event the non-quenching parallel coils or groups remain superconducting (i.e., their current is below critical current and there are no mechanical or thermal events that may cause these coils to quench), then the quench is limited to only the quenched coil or group. In some cases, the equipment may continue operation after quench, although at a somewhat reduced capacity. The proposed approach is potentially more advantageous for superconducting systems that consist of many similar coils with relatively weak inductive coupling.

Speaker: Michael Parizh (GE Global Research) -

9

Mon-Mo-Po1.01-09 [8]: Experimental Study on the Electrical Properties of Optical Fiber Encapsulated High Temperature Superconducting Tapes

Previously, we verified the feasibility of using a Raman-based distributed temperature sensor (RmDTS) system to measure a no insulated (NI) high temperature superconducting (HTS) coil temperature variation during an overcurrent induced quench event. In addition, to reduce the temperature response time of the RmDTS, we further optimized the whole measurement system. However, the combination method between optical fibers and HTS coil in these works is immobilizing spiral optical fibers on the turn-by-turn surface of HTS coil by using epoxy which could be harmful for the structures of HTS coils. Therefore, an ideal combination structure that encapsulating optical fibers in HTS tapes along the length direction was proposed. Before winding HTS coils, the electrical properties of these optical fiber encapsulated HTS tapes (OFE-HTS tapes) should be studied in advanced. In this study, we have compare the vibration of the critical current values, resistive values at room temperature, anti-impulse current characteristics of normal HTS tapes and OFE-HTS ones. The foundational study can really promote the RmDTS application for quench detection. More detailed experimentation and comparison results will be presented and discussed in this paper.

Speaker: Z.Y. Li -

10

Mon-Mo-Po1.01-10 [9]: A Conceptual Design of “Magnetic Dam” as a Quench Protection System Using Electromagnetically Coupled Coils for NI HTS Magnet

When a quench occurs in a high field no-insulation (NI) high temperature superconductor (HTS) magnet that consists of a stack of double-pancake (DP) coils, a large amount of current is often induced in an NI DP coil that is electromagnetically coupled with neighbor DP coils. Depending on the strength of external magnetic field, the large induced current leads to an excessive magnetic stress and occasionally damages the magnet. In this paper, we propose a new quench protection concept to reduce the amount of induced current in an NI HTS magnet. The key idea is to use resistive copper within the magnet windings in order to absorb a portion of electromagnetic energy that is initially stored in the magnet before the quench. We tentatively name these resistive coils or plates as a “magnetic dam”, as they may slow down the electromagnetic quench propagation speed among the NI DP coils, which may be beneficial to avoid the mechanical damage by the large over-current.

Acknowledgement

This work was supported by Samsung Research Funding & Incubation Center of Samsung Electronics under Project Number SRFC-IT1801-09.Speaker: Mr Soobin An (SeoulNationalUniversity) -

11

Mon-Mo-Po1.01-11 [10]: Experimental study on quench protection of HTS magnet composed of multiple pancake-coils by use of auxiliary resistive shunt loop method

HTS coils wound with insulated wires are actually quenched, even though HTS wires have a high quench margin and can be easily damaged, if the quench protection system does not work properly, especially in the case that current density of the magnet wires is high, It should be noted that the training effects as in LTS magnets have not been observed in HTS magnets and that damaged HTS magnets cannot be reused. Therefore, protection of HTS magnets from quench damage is important for their repeated use. The most probable cause of quench damage of HTS magnet is over-heating at the highest temperature spot (hot-spot) in the magnet wire during the quench protection sequence. Therefore, to avoid damage, it is necessary to reduce heat generation in the hot-spot. In a previous work, the authors proposed a quench protection method to reduce hot-spot temperature and increase quench detection voltage to protect an HTS magnet composed of multiple pancake sub-coils from quench damages. In the method, a current of a quenching sub-pancake coil is transferred to the other sub-coils of the magnet forming auxiliary resistive shunt loop (ARSL) by resistively shorting the other sub-coils. In this work quench behaviors of the pancake sub-coils of a model magnet was investigated by simulation experiment using small scale test pancake coils wound of YBCO wire. Current patterns of the sub-pancake coils of a model magnet at a quench event were calculated for the case that ARSL method was applied. In the experiment, the same patterns of currents calculated for the model magnet were applied to the quenching test coils by a controllable current supply. Experimental results show effectiveness of the proposed method.

Acknowledgements

This work is based on results obtained from a project commissioned by the New Energy and Industrial Technology Development Organization (NEDO).Speaker: Takuma Ichikawa (university) -

12

Mon-Mo-Po1.01-12 [11]: Cenceptual Design and Performance of Quench Detection System for Super High Field Magnet Using Multi Receivers via Wireless Power Transfer Technology

The superconducting wires have been developed for high field magnet, transformers, motors and so on. The quench detection and protection system are essential for safety operations of the HTS facilities. The high voltage signal conditioner (HVSC) method is generally used for the quench detection and protection, however, especially for high voltage operation magnet such as international thermonuclear experimental reactor (ITER) magnet (56 kV, DC), it is difficult to apply to HVSC method due to the risks in terms of high voltage sparks. As well as, the power supply for HVSC should be isolated since the super high field magnet such as ITER magnets, which is supplied by 15 MA, generate about 10 T (tesla) strong magnet. To solve these problems, insulation resistance of power supply should be larger than 500 MΩ; a lower resistance can affect the common-mode voltage of the differential amplifier in the HVSC system. From these reasons, our research team, the wireless power transmitter (WPT) system has been considered as one of reasonable options to solve insulation resistance obstacles since WPT system can transfer power through any non-metallic media between antenna (Tx) and receiver (Rx) coils. Now, the one wireless power system generally supplies operating power for one differential amplifier in the HVSC. Practically, numerous differential amplifiers would be installed in the high field magnet to detect and protect magnet system. From this reason, in this study, authors described the conceptual design and fundamental performances of quench detection system for super high field magnet using wireless power technology. Especially, the thermal distribuitons of antenna and receiver will be evaluated. As well as, the number of wireless power supply including insulation resistance can be reduced by multi resonance receiver under the 100 kHz with 3kW RF generator.

Speakers: Yoon Do Chung (Suwon Science College), Yojong Choi (Yonsei University, Seoul, Korea) -

13

Mon-Mo-Po1.01-13 [12]: Dynamic quench protection framework for nuclear fusion energy devices based on superconducting magnet testing

The Large-scale Superconductor Test Facility (LSTF) serves as an important part of superconducting magnet load testing for fusion research which concerns about the nuclear energy producing. During the testing process, quench protection (QP) is indispensable for protecting the load from being overheated damaged. In this paper, a compatible and flexible QP framework is put forward to meet the different QP requirements including transferring time, protection voltage, the temperature raise, current decay speed and so on. The QP framework can provide the solution of changing the power units parameter on account of specific testing superconducting magnet. Firstly, the LSTF is introduced and the QP process in the system is comprehensively analyzed by discussing the power units’ actions and circuits currents’ flowing. Then the power units of QP system are studied by elaborating the power parameters adjustments in corresponding to different loads, especially the counter-pulse capacitor unit and the fast discharge resistor system. Finally, the testing process of central solenoid coil used for the China Fusion Engineering Test Reactor is described to illustrate the operation of the QP framework.

Speaker: Kun Wang (Institute of Plasma Physics Chinese Academy of Sciences (ASIPP))

-

2

-

Mon-Mo-Po1.02 - Multiphysics Design and Analysis I Level 2 Posters 1

Level 2 Posters 1

Conveners: Victor Bykov (Max Planck Institute for Plasma Physics, Greifswald, Germany), Walter Fietz (KIT)-

14

Mon-Mo-Po1.02-01 [13]: Parametric Sensitivity Characteristics of Numerical Simulations on EMF Free Bulging of Circular Sheet Metal

Electromagnetic forming (EMF) processes of sheet metal are used to manufacture several components in modern industry. The EMF process is a highly nonlinear phenomenon and its understanding is a complex task due to the coupling of the electrical, magnetic, thermal and mechanical problems. The generated electromagnetic forces in this process are directly correlated to the resulting deformed workpiece geometry and strongly dependent on EMF system parameters as capacitance, initial capacitor energy, tool geometry, and its electrical conductivity, inductance, and mechanical properties. This study focuses on performing a parametric sensitivity analysis by numerical simulations of free bulging of circular sheet metal aiming a high and adequate force distribution from the EMF system. The numerical method solves the electromagnetic problem using an in-house script implemented in Matlab and then the mechanical problem is solved using the ABAQUS/Explicit Finite Element software. In the presented method, the EMF process is treated as fully coupled electric-magnetic and uncoupled with the mechanical problem, solving electrical circuits, identifying their parameters, and presenting calculations method for the magnetic flux density, the self and mutual inductances, and the electromagnetic force distribution regarding coil geometry to the initial time instant. The electromagnetic force calculated with Matlab is employed in a user subroutine of ABAQUS/Explicit to predict the movement of the workpiece. The research methodology involves a parametric sensitivity analysis considering the following design variables parameters of EMF devices: system capacitance, energy pulse, and tool coil geometry. Finally, conclusions and design principles for the free bulging of sheet metal by EMF are outlined.

Speaker: Prof. Evandro Paese (Departamento de Engenharia Mecânica, Universidade de Caxias Sul, Campus Universitário da Região dos Vinhedos) -

15

Mon-Mo-Po1.02-02 [14]: Progress in Simulation Method of No-Insulation High Temperature Superconductor Magnets

Rare earth barium copper oxide (REBCO) coated conductor has been promising conductor for the design of high field magnets due to its high strength, high critical current and high critical field. However, high temperature superconducting (HTS) magnets are challenging to protect due to slow normal zone propagation velocity (NZPV). No-insulation (NI) winding technology has been demonstrated to produce compact, reliable, stiff and strong magnets. This technology is not devoid of its own challenges either. The charging delay due to radial bypass path in NI coil is an actively researched area. To verify that such magnets are truly self-protecting and to understand other unique behaviors of NI magnets, they are modeled using “lumped circuit model” where each “sub-coil” is modeled as a single inductor with resistances in series (quench resistance, Rq) and parallel (characteristic resistance, Rc). The results obtained using this method and lessons learned are presented in this article: (1) During fast electromagnet quench propagation of NI magnets, overcurrents (currents greater than designed operating current) are produced which can overstress the magnets. (2) Variation of Rc with temperature and magnetic field can influence the magnet voltage. (3) In asymmetric quench of nested NI magnets, the axial centering force can be large and need to be considered. (4) Screening current and its effect in field homogeneity and magnet stress is also an important challenge unique to NI magnets. Despite the challenges, the work presented here shows that it is possible to construct high field magnets using NI REBCO technology after careful consideration of these challenges and lessons learned which will be beneficial for advancing the area of HTS magnet development.

Speaker: Kabindra Bhattarai (National High Magnetic Field Laboratory) -

16

Mon-Mo-Po1.02-03 [15]: Update of Joule Losses Calculation in the ITER Cold Structures during Fast Plasma Transients

As part of the design justification of the ITER magnet system and in preparation of the commissioning activities, the heat deposition on the ITER cold structures has been computed in order to generate input loads for subsequent thermo-hydraulic analyses, which are essential for the assessment of the temperature margins of the superconducting cables. The Finite Element model of a 40 degree sector of the ITER magnet system presented in [1] has been updated, including Poloidal Field (PF) coils clamps and Correction Coils (CC) supports. A new inductive plasma scenario (DINA-2017) as well as the Toroidal Field (TF) coils fast discharge have been simulated with the electromagnetic code CARIDDI. The results are in line with the old computations. In addition to these events, the effects of the voltage ripple generated on the TF coils by the power supply have been analyzed and the induced eddy currents assessed.

[1] F. Cau et al., “Joule Losses in the ITER Cold Structures During Plasma Transients”, IEEE Transactions on Applied Superconductivity, vol. 26, no. 4, Apr. 2016.

Speaker: Francesca Cau (Fusion for Energy) -

17

Mon-Mo-Po1.02-04 [16]: Presentation withdrawn

-

18

Mon-Mo-Po1.02-05 [17]: Stress Distribution of Magnetically Controlled Reactor Core in Gaps Area under Simulated Service Conditions

In order to control and reduce the vibration of magnetically controlled reactors(MCRs) with gaps core structure, accurate stress computation should be carried out. Previously, researchers proposed a finite element model for reactors core stress calculation considering Maxwell stress theory and magnetostriction effect. Giant magnetostrictive materials are used to be filed into the gaps to reduce the electromagnetic force in iron cores between gaps. However, they did not compute MCRs core stress considering the hardness of the gap filler under service condition.

Under the MCRs service condition of AC and DC excitations, the main factors which have influence on stress distribution in gaps area include magnetostriction effect of silicon steel, electromagnetic force effect of iron cores between gaps and the hardness of the gap filler. The magnetostrictive stress and electromagnetic stress have been studied, but the influence of gaps filler hardness on the total vibration of MCRs has not been analyzed. This paper presents an electromagneto-mechanical coupled model for MCRs to analyze their stress distribution under service condition. Firstly, magnetostriction and magnetization properties for oriented electrical steel sheet along the rolling direction (RD) and the transverse direction (TD) under AC and DC excitations are tested. Then, based on the measured constitutive relations, an electromagneto-mechanical coupled model for MCRs considering electromagnetic force effect, magnetostriction effect and the hardness of inserted materials is presented and the stresses in different directions in gaps area are calculated. Finally, an MCR prototype is made and the core vibrations in gaps area under different AC and DC excitations are tested to prove the validity of the proposed model. From the calculated and experimental results, it can be seen that the vibration in the outer edge of cores is more serious than that in the center of cores.Speaker: Long Chen (China Three Gorges University) -

19

Mon-Mo-Po1.02-06 [18]: Magneto-Mechanical Analysis of A Racetrack Superconducting Magnet Using Multiscale Approach

ABSTRACT: The large range of length scales presents within superconducting magnet and its heterogeneity, a straightforward numerical simulation of a magnet, considering all details of the microstructures would cost enormous time, so incorporation of the multiscale approaches into computational models can facilitate the numerical analysis. Additionally, the superconducting magnet with high transport current and intense magnetic field are often exposed to large Lorentz forces, which lead to the unavoidable deformation in superconducting coils, the deformation will further disturb the quality of the magnetic field. In this work, the stress/strain and magnetic field of a 4T NbTi/Cu racetrack superconducting magnet were numerical analyzed, a multiscale model from the NbTi filament scale to the coil scale was developed to obtain the homogenized and the orthotropic material properties of the superconducting coil based on the representative volume element (RVE) and rule of mixture of composite methods, these material properties are employed to solve for stress/strain and magnetic field development by using three-dimensional finite element method (FEM), and taking into account the effect from magneto-mechanical coupling of superconducting coils. The study shows that the numerical predictions based on multiscale approach for the superconducting coils on the strain are in better agreement with the previous experimental data than those based on a single-scale approach, and shows the magneto-mechanical coupling behavior of the superconducting coils is remarkable especially in intense magnetic field and large transport current. The FEM based on multiscale model was demonstrated as an acceptable method to estimate the required material properties of the superconducting coils for the magneto-mechanical analysis of a superconducting magnet.

Key words: multiscale model, magneto-mechanical coupling, FEM, superconducting magnet.Speaker: Qiang Hu (Key Laboratory of Mechanics on Western Disaster and Environment, Ministry of Education, College of Civil Engineering and Mechanic, Lanzhou University, Lanzhou, China; Institute of Modern Physics of Chinese Academy of Science, Lanzhou, China;) -

20

Mon-Mo-Po1.02-07 [19]: User Defined ANSYS Elements for 3D Multiphysics Modeling of Superconducting Magnets

Computational modeling of superconducting magnets allows for predicting and understanding magnet behavior. The commercial software ANSYS is a widely used finite element software for mechanical, thermal, and electromagnetic modeling of superconducting magnets. ANSYS also allows its user to create custom elements by programming the elements’ properties and its finite element matrices. These user elements can capture additional material properties and physics that current ANSYS elements do not. Once compiled, they are then compatible with all other aspects of the software, including geometry generation, meshing, solving, and post-processing. Additionally, these elements can also be used with the multiphysics solver. We have developed two 3D user elements, one thermal and one electromagnetic with circuit coupling. In addition to the basic capabilities of ANSYS, they capture quench propagation, interfilament coupling currents, current sharing, and temperature and field dependent material properties. Two-dimensional user elements have previously been developed; however, modeling superconducting magnets in 3D allows for better representation of end effects, and other non-symmetric physics. Using the ANSYS multi-field solver, these two elements are shown to simulate coupled transient electromagnetic, thermal, and circuit effects for Nb3Sn undulators and other magnets built and tested at Lawrence Berkeley National Laboratory, particularly within the MDP. The effects of quench, interfilament coupling currents, and structural eddy currents are studied and compared to magnet test data while steps towards parallelization are also explored.

Speaker: Ms Kathleen Edwards (Lawrence Berkeley National Laboratory) -

21

Mon-Mo-Po1.02-08 [20]: Accurate calculation of field expansion coefficients in FEM magnetostatic simulations

FEM simulations are a standard step in the design of accelerator magnets. It is custom for accelerator applications to characterize the field quality in terms of field expansion coefficients. Expansion coefficients are usually calculated by means of a Fourier transform of the local FEM solution evaluated at points on a circle (2D) or cylinder (3D case). The accuracy of the coefficients calculated this way depends strongly on the FEM mesh configuration and simple refinement of the mesh does not always improve accuracy. The accuracy of the expansion coefficients calculation can be improved by using the data on the magnetization of elements in the magnet yoke, obtained in the solution, instead of using directly the local solution. Since currents and the yoke magnetization are the only sources of the field, with these data the field expansion coefficients can be calculated at any remote point. We derive closed forms for calculating expansion coefficients and implemented these results in the ANSYS® add-on. Results for a case study are presented, which demonstrate that expansion coefficients can be calculated with good accuracy even for a rather coarse mesh.

Speaker: Dr Vasily Marusov (GSI Helmholtzzentrum für Schwerionenforschung GmbH) -

22

Mon-Mo-Po1.02-09 [21]: HTS magnetization current simulation using ANSYS iterative algorithm method and user defined element

Kai Zhang, Sebastian Hellmann, Marco Calvi

Paul Scherrer Institut, Villigen, CHLucas Brouwer

Lawrence Berkeley National Laboratory, Berkeley, CAAbstract – In this work, we will introduce the feasibility of using A-V formula in ANSYS to simulate the magnetization process of HTS bulk materials. The iterative algorithm method (IAM) based on ANSYS APDL is firstly developed to simulate the magnetization current issues in a ReBCO bulk disk based on Bean model. Specifically, we confirm it is feasible to simulate the development of trapped current density in the ReBCO bulk during the process of ramping and damping the external magnetic field. Using IAM, we can update the magnetic field-dependent critical current density for each element in the ReBCO bulk after each load step of electromagnetic analysis. It is also feasible to take the mechanical strain effects into consideration if we update the strain-related critical current density after each load step of electromagnetic-mechanical coupled analysis. Finally, a systematic study of HTS magnetization current issues is performed to test the newly developed ANSYS user defined element (UDE) in which E-J power law is defined. The flux creep effects of the ReBCO bulk during Field Cooling Magnetization (FCM) are investigated when using different n-values. The simulation results of using ANSYS IAM and UDE are compared with the simulation results of using COMSOL.

Speaker: Dr Kai Zhang (Paul Scherrer Institut) -

23

Mon-Mo-Po1.02-10 [22]: Design and Optimization of a High-frequency Rotational Magnetizer for Nanocrystalline Alloys Based on Improved SVM and PSO Algorithms

Characterizing the magnetic properties of industrial magnetic materials has great significance on the development of transformers, motors and other electrical equipment. Recently, high-frequency and high-power density electrical equipment has attracted more attention. As the frequency is getting higher and higher, the losses of the magnetic core are much higher than that in the power frequency situation. Nanocrystalline and amorphous alloys lead to a significant reduction in the core loss which gives the opportunity to develop high-efficiency devices in high-frequency applications under frequencies from 20 Hz to 20 kHz. For better using of these materials, it is very necessary to have a deep understanding of these materials’ loss behavior under rotational magnetization condition. In this paper, a new magnetizing structure for nanocrystalline alloys rotational core loss measurement is designed and optimized by the 3D-FEM method. The optimization goal is to achieve both the best homogeneity and the highest testing frequency. As the affecting factors are very complex and the 3D-FEM calculation is very time consuming, improved SVM and PSO algorithms are combined in the optimization process. The improvement of PSO is one of the significant parts of this paper. PSO is a kind of swarm intelligence algorithm. It is simple and easy to implement. But it also has the problem of low search accuracy and is easy to fall into local extrema. In this paper, an improved PSO called the velocity-controlled PSO (VCPSO), based on the analysis of the particles’ distribution has been developed and used in the optimization process. As the 3D FEM calculation is very complex, support vector machine (SVM) is used to establish a regression model between the designed parameters of the RSST during the optimizing process. The results well detailed discussed in the full paper.

Speaker: Dr Long Chen (China Three Gorges University)

-

14

-

Mon-Mo-Po1.03 - High Field Magnets for Accelerators Level 2 Posters 1

Level 2 Posters 1

Conveners: Karie Badgley (Fermilab), Peter McIntyre (Texas A&M University)-

24

Mon-Mo-Po1.03-02 [23]: Fracture Failure Analysis for MQXFA Magnet Aluminum Shell

The High-Luminosity LHC Accelerator Upgrade Project (HL-LHC AUP) is approaching the production phase of the US-contributed Q1 and Q3 Interaction Region Quadrupoles (MQXFA). The structures for the MQXFA prototypes were design and inspected by the US-LARP (LHC Accelerator Research Program), AUP developed criteria, which will be used for the pre-series structures. As the first two full-length prototypes with 4.2 m magnetic length, MQXFAP1 and MQXFAP2, were designed and assembled at Lawrence Berkeley National Laboratory (LBNL), and tested at Brookhaven National Laboratory (BNL). The end aluminum short shell of MQXFAP2 was fractured along the shell length during the test, and tests were stopped. Analytical and Finite Element analysis were performed in light of the graded procedure defined in the Structure Design Criteria to investigate the fracture failure for MQXFAP2.

In this paper, we report the fracture analysis of the current shell design, including the elasto-plastic simulations with sub-model technique, crack propagation simulations, and calculations with Linear Elastic Fracture Mechanics (LEFM). Test material properties are also presented. The results of this analysis explain why the end shell of MQXFAP2 failed, and suggest fillets on the end shell notches to meet the margin specified in the Structural Design Criteria.Speaker: Heng Pan (LBNL) -

25

Mon-Mo-Po1.03-03 [24]: Performance update of 2-m-long 11 T Nb3Sn dipole magnet models for HL-LHC

In the frame of the HL-LHC upgrade, assemblies of two 5.5 m long 11 T Nb3Sn dipoles (MBH) are expected to replace 8.3 T NbTi LHC main dipoles (MB). Double and single aperture models, each 2 m long, were built and cold tested in operational conditions. The models have design features that are verified during these tests to provide feedback for the technology development of 5.5 m full-size magnets. With the last model magnets tested, using the final conductor, conductor insulation and assembly processes, the performance is evaluated and the readiness for series production is confirmed. In this paper, the test results of the latest model magnets in terms of training behaviour and memory, conductor limits, endurance, quench protection and other cold powering tests are presented. Additionally the results of cold endurance tests, thermal cycles and powering cycles, are discussed in view of the operational requirements in the LHC.

Speaker: Gerard Willering (CERN) -

26

Mon-Mo-Po1.03-04 [25]: Analysis of quench in the HL-LHC 11 T dipole model magnets with 1-D and 2-D models

The HL-LHC Project at CERN requires the installation of 11 T Nb3Sn dipole magnets to upgrade the collimation system. Given the high operating field and current density, the quench protection of these magnets is particularly challenging. The baseline protection scheme of the 11 T dipoles is based on the quench heaters technique.

Dedicated quench tests were carried out at CERN on short samples of the 11 T dipole magnets, in which the quench heaters were fired either individually or simultaneously. The aim of these tests was to measure the quench energy and quench location in the coils, in response to heat depositions of different amplitude. The tests were carried out at transport currents in the range from 11.85 and 12.85 kA; the applied heat flux densities were increased stepwise between 5.9 and 12 W/m until a quench was detected.

Two different modeling approaches were developed to analyze the test results. The first model is based on a simplified 1-D representation of the magnet components along a line crossing radially the middle plane of one quadrant of the magnet cross section. To improve the description of heat exchange with superfluid helium, this model was also applied to analyze dedicated tests carried out in the cryogenic facility of CERN.

The second model represents in detail all magnet components in the 2-D cross section of one dipole quadrant. The model allows one to identify the parts of the magnet which are more thermally solicited in the quench tests, and therefore the most probable quench initiation locations.

The paper presents a detailed description of the models, their validation by comparison with the experimental results, and their application to analyze the details of the quench propagation in the magnet cross section.Speaker: Marco Breschi (University of Bologna) -

27

Mon-Mo-Po1.03-05 [26]: Geometrical Inspection and Analysis of the Impregnated Nb3Sn 11 T Coils

In the CERN Large Magnet Facility (LMF), the series production of the Nb3Sn-based 11 T dipole magnets is currently ongoing. Results from magnet tests and observations regarding the conductor irreversible stress limitations have shown that a uniform and well-defined pre-load is crucial. The collaring force in the assembly is adjusted by the thickness of a longitudinal shim derived from the measured coil’s azimuthal excess. One of the key features to define the collaring force is given by the control of the coil dimensions. The results from two measurement setups are presented using Coordinate Measurement Machines (CMM) featuring ±34 μm and ±5 μm accuracy. The analysis accuracy is modelled taking into account the 11 T coil branch geometry and measurement setup characteristics.

Speaker: Friedrich Lackner (CERN) -

28

Mon-Mo-Po1.03-07 [27]: Analysis of the heater-to-coil insulation in MQXF coils.

In the framework of the HiLumi project, the present LHC low-β superconducting quadrupoles will be substituted with more performing ones, named MQXF. MQXF will have high peak-field on the conductor (~12 T), therefore the Nb3Sn technology is needed in order to reach the target performance.

One of the main technological challenges for the Nb3Sn magnets is the coil fabrication: due to the brittleness of Nb3Sn, coils needs to be impregnated with epoxy resin in order to improve mechanical properties, and avoid conductor damaging. Quench heaters are necessary for quench protection, and they need to be impregnated with the coil as well, in order to be close enough to the coil itself and to reach the required efficiency. Quench heaters are insulated from the coil by a 145 μm layer S 2 Glass® and Epoxy resin, and a 50 μm layer of Kapton®.

The test of the first MQXF prototype (4 m long) has been interrupted due to a heater-to-coil short circuit. Therefore, the electrical testing procedures have been improved, and a deep analysis of the heater-to-coil insulation has been performed.

In this paper, we report the results of the heater-to-coil insulation analysis, showing the simulations of the peak voltages expected in the magnet, modelling of the insulation during quench and electrical test conditions, including failure analysis, and the experiments performed on coil sections, short coils and models, long coils and prototypes made in order to prove the robustness of the insulation. Alternatives to the present fabrication solution are also presented, showing advantages and disadvantages. The results of this analysis are of general interest for all the Nb3Sn coils impregnated together with quench heaters.Speaker: Vittorio Marinozzi (FNAL) -

29

Mon-Mo-Po1.03-08 [28]: Vacuum impregnation of long Nb3Sn coils for the HL-LHC project

The CERN Large Magnet Facility (LMF) is currently producing 5.5 m long 11 T dipole and 7.2 m long MQXFB quadrupole coils for the HL-LHC project. Both coil types are fabricated with Nb3Sn conductor and therefore produced based on the so-called wind and react process. These coils require a vacuum impregnation process to form the final electrical insulation.

The paper will present the impregnation process applied at CERN, together with the one used in the US for the MQXFA coils, within the Accelerator Upgrade Program (AUP) framework. The impregnation process and its reproducibility are shown, ongoing developments to further improve quality control are proposed. Furthermore, the LMF impregnation infrastructure and recent applied upgrades are described, aiming for a reliable process workflow based on a modular hardware with an improved interchangeability.Speaker: Mr Jerome Axensalva (CERN) -

30

Mon-Mo-Po1.03-09 [29]: Characterization of NbTi busbar for HL LHC Interaction Region Quadrupoles

The United States High Luminosity Large Hadron Collider Accelerator Upgrade Project (US-HL-LHC AUP) is designing and fabricating 11 Q1/Q3 cold masses for the interaction regions of the LHC. Each cold mass contains two 4.2 m quadrupole magnets. The Nb3Sn quadrupole magnets operate in superfluid He at 1.9 K with a nominal field gradient of 132.6 T/m. The design and fabrication of the through and local buses for the cold masses is carried out at Applied Physics and Superconducting Technology Division at Fermilab (FNAL). The bus-bars consist of two superconductive NbTi cables soldered together and wrapped in Kapton.

This paper reports the characterization of the bus-bar thermo-electric properties to validate the bus design and assure quench protection. Calculations have been performed to estimate the quench integral, the quench propagation velocity and the maximum voltage developed in the bus. The bus design was validated testing the cable together with a short Nb3Sn magnet in the vertical test facility of Applied Physics and Superconducting Technology Division at FNAL.

The test demonstrated that the bus design is sound; no spontaneous quench took place up to 17870 A current value. Temperature margins were measured to be higher than the required 5 K for the High-Luminosity Q1/Q3 triplet bus at nominal operating current. Protection studies revealed that the bus can be adequately protected using 100 mV voltage threshold value for the entire current range the magnet will operate in the LHC tunnel. Results of quench propagation velocity and quench integral measurements as a function of temperature and current are also presented in this paper.Speaker: Maria Baldini (Fermi national accellerator laboratory) -

31

Mon-Mo-Po1.03-10 [30]: Design of a Compact Support Structure for a High Gradient Niobium Tin Superconducting Magnet for a Proposed Electron Ion Collider (EIC).

Abstract— A future Electron Ion Collider (EIC) may require high gradient superconducting quadrupole magnets for final focusing of the hadron beam in the interaction region. Due to the closeness to the beam collision point and the narrow 25mr crossing angle these high gradient magnets will reside in close proximity to electron beam magnets, thereby requiring a very compact support structure in comparison with typical accelerator magnet support structures, for the high Lorentz forces that are generated with excitation. This paper reports on the design of a proof of principle support structure for a 132 T/m, 120mm aperture superconducting magnet, utilizing the (HQ) coil design developed for the LHC Accelerator Research Program (LARP). In addition to the design work a 15cm long mechanical model based on the design is being built and loaded to the required level of coil precompression at room temperature, and then cooled to 77K to also confirm the level of coil precompression at cryogenic conditions. Future work will include construction and testing of a proof of principle magnet based on the design in an accelerated time frame, utilizing previously tested LARP HQ coils.

Index Terms—EIC, LARP, Hi-Lumi, LHC, Nb3Sn, superconducting magnets

Speaker: Ms Kathleen Amm (BNL) -

32

Mon-Mo-Po1.03-11 [31]: Test of a single Nb3Sn sextupole coil for ECR ion source using a mirror structure

IMP is developing a Nb3Sn superconducting magnet system for a 45 GHz electron cyclotron resonance (ECR) ion source. To achieve this complicated and difficult Nb3Sn magnet, a prototype with identical cross section but half length of the magnet is proposed. Recently a single sextupole coil about 0.5 m long has been fabricated and tested. The coil has a bore size of 200 mm and was wound by using a Nb3Sn wire with 1.3 mm diameter. In order to test the coil efficiently, a mirror structure is utilized. And the Bladder & key technology is employed to exert the required preload on the coil. This paper describes the magnetic field design of the sextupole mirror structure, presents the fabrication of the sextupole coil and reports the test results.

Speaker: Dr Wei Wu -

33

Mon-Mo-Po1.03-12 [32]: Final focus superconducting magnets for CEPC

Circular Electron Positron Collider (CEPC) with a circumference about 100 km, a beam energy up to 120 GeV is proposed to be constructed in China. Most magnets for CEPC accelerator are conventional magnets, except some superconducting magnets are required in the interaction region of CEPC collider ring. High gradient final focus doublet quadrupoles QD0 and QF1 are required on both sides of the collision points in the interaction region of CEPC collider ring to achieve high luminosity. QD0 and QF1 are both double aperture superconducting quadrupoles with a central field gradient of 136 T/m and 110 T/m, respectively. The field crosstalk between the two apertures in the quadrupoles should be solved. Since the final focus superconducting quadrupoles are operated inside the field of the Detector solenoid magnet with a central field of 3.0 T, strong superconducting anti-solenoid is need to cancel the Detector solenoid field and minimize the effect of the solenoid field on the beam. In this paper, the layout and magnetic design of CEPC final focus superconducting magnets are described, and the R&D status of prototypes superconducting magnets is presented.

Speaker: Dr Yingshun Zhu (Institute of High Energy Physics, Chinese Academy of Sciences) -

34

Mon-Mo-Po1.03-14 [33]: A High Precision Magnetic Field Shimming algorithm for Inclined 45° Continuous Cutting on Spiral Pole of SC Cyclotron

Due to the small size and low power consumption, compact superconducting cyclotron are suitable to be installed in hospital for cancer therapy, which becomes a research hotspot in recent years. China Institute of Atomic Energy has been developing a 230MeV compact superconducting cyclotron CYCIAE-230 to meet the demands of proton therapy in China. Accelerator physics design requires a strict control of the average field error and first harmonic in the main field. A processing method of inclined 45o continous cutting on the two pole edges is proposed to shim the field in CYCIAE-230. For a spiral sector magnet, the 45o continous cutting generates an asymmetrical magnetic field on both sides, and the field change is not proportional to the milling depth, which makes the establishment of the shimming algorithm much more complicated. In this paper, a Mathematica model of the linear equation for field shimming calculation is established. The field change caused by the local cutting is calculated numerically by the integral equation method to describe the nonlinear relation of the complex shape cutted parts. And then the shimming process is built with multi-iterative simulation based on the least squares method. The finite element model is built to confirm the field change brought by the inclined 45o cutting value, which is added to the iterative calculation for cutting value correction and expecting the shimming effect. The new shimming algorithm is applied for the field measurement, amending and processing of CYCIAE-230, which achieve significant results to reduce the shimming times and further the fabrication period. The process of the shimming algorithm and the corresponding shimming effect of CYCIAE-230 will be presented as well.

Speaker: Dr Ming Li (China Institute of Atomic Energy) -

35

Mon-Mo-Po1.03-15 [34]: Magnetic Field Measurement, Amending and Processing for 230MeV Superconducting Cyclotron Main Magnet

A 230 MeV superconducting cyclotron CYCIAE-230 is being constructed by the China Institute of Atomic Energy. The technology of magnetic field measurement and amending processing is the primary task to realize the isochronous acceleration of cyclotron. The CYCIAE-230 has higher magnetic field, higher field gradient and dense rotation orbits. Therefore, the isochronous field and resonance crossing amended simultaneously. The first harmonics is also shimmed at the same process to achieve about 80% of the extraction efficiency by using resonance and precession extraction. The precision of field measurement, amending and processing is much higher and the algorithm is much more difficult. In addition, the compact structure of the magnet has very narrow installation space, which makes mapper design more difficult. In this paper, we will introduce:

1.The asymmetric field amending method for spiral sectors of SC cyclotron based on 45 degree chamfering on the pole edge is proposed and implemented for the first time. This method can effectively shim the isochronous field and first harmonics, reduce the magnetic saturation surround the pole edge, and facilitate the installation of main components such as central region and RF cavity.

2.During the processing, the asymmetric amending on both sides of the spiral sectors is creatively introduced to adjust the local tune value, so as to avoid the beam staying near harmful resonance and realize the effective control of the beam quality in the cyclotron.

3.A automated magnetic field measurement device, with both searching coil and hall probe has been developed. A series of optimum design and implementation of mechanical parts and EMC have effectively improved the positioning accuracy, greatly reduced the interference signal, and achieved the relative field measurement accuracy of 5×10-5.

After four times of field measurements, amending and processing, the results show that the phase shift, tune value and first harmonics have achieved excellent results. Detailed process will also be given in this paper. Such results will benefit greatly the overall performance of CYCIAE-230.Speaker: Prof. Tianjue Zhang (China Institute of Atomic Energy) -

36

Mon-Mo-Po1.03-16 [35]: Preliminary Study of the High Temperature Superconducting Solution for 2GeV CW FFAG Magnet

Proton beam with an average power of 5MW-10MW have important applications in particle physics towards the intensity frontier, as well as in the advanced energy, and material science. The fixed field alternating gradient (FFAG) accelerator combines the advantages of existing accelerators, which has a higher limitation of beam energy than high power cyclotron and has a higher beam-to-grid efficiency than existing high power linac and synchrotron, thus is considered as a good candidate for high power proton machine.

By utilizing the strong focusing and large acceptance features of FFAG in the theoretical framework of the fixed field and fixed frequency of isochronous cyclotron, a 2GeV/6MW continue wave FFAG design has been proposed in China Institute of Atomic Energy (CIAE). Due to the beam loss of high power proton beams, the resulting high radiation will deposit a large amount of radiation dose and head load on the SC magnet. As the high temperature superconductors (HTS) have a much larger thermal margin due to high critical temperature (> 90 K) and high upper critical field (> 100 T) than the traditional low temperature superconductors, and have been also considered have the lower overall construction costs and power consumption than the conventional magnet, currently the HTS magnet is the favorable solution for the 2GeV FFAG magnet design. In this paper, the lattice design along with the requirements on the F-D-F magnet of the 2GeV FFAG design is briefly introduced first. Then, the design of the F-D-F magnet is outlined. And the details of the HTS coil design utilizing ReBCO conductor and operating at ~40 K is also included.Speakers: Dr Ming Li (China Institute of Atomic Energy), Tianjue Zhang (China Institute of Atomic Energy)

-

24

-

Mon-Mo-Po1.04 - High Field Magnets for Future Colliders Level 2 Posters 1

Level 2 Posters 1

Conveners: Friedrich Lackner (CERN), Qingjin XU (IHEP, CAS)-

37

Mon-Mo-Po1.04-02 [36]: 3D mechanical Analysis of the Block-coil Dipole option for the future Circular Collider

This paper presents a 3D mechanical analysis study of the mechanical behaviour of the complete magnet structure of the Block-coil Dipole option for the future Circular Collider. The analysis includes three steps: (i) pre-loading with bladders and keys, (ii) cooling down from room to operating temperature, (iii) ener-gization at operating temperature. The main objective of the 3D optimization is to contain the large elec-tromagnetic forces, both in the straight section and in the coil ends. The optimization must guarantee that the stress level in the coil and in each component of the structure remains lower than the allowable values at each loading step. The magnet design in the straight section has been optimized and validated previous-ly using a 2D model. A 3D model is then required to optimize the coil ends and the longitudinal sup-port.This study was performed in the framework of the EuroCircol project.

Speaker: Mr Chhon Pes (CEA) -

38

Mon-Mo-Po1.04-03 [37]: Engineering Design and Digital Twin of the Nb3Sn 16T main dipole magnet of the FCC accelerator

Superconducting accelerator dipole magnets, based on Nb3Sn technology, with a nominal operation field of 16 T in a 50 mm aperture are being considered for the Future Circular Collider (FCC) with a center-of-mass energy of 100 TeV and a circumference in the range of 100 km, or an energy upgrade of the LHC (HE-LHC) to 27 TeV. To demonstrate the feasibility of such magnets, a twin-aperture 16T Nb3Sn dipole demonstrator based on a 4-layer cos-theta coil with 50 mm aperture and cold iron yoke is developed in the frame of the EuroCirCol program. The main design challenges for 16 T magnets include large Lorentz forces at this field level while maintaining accelerator requirements. To counteract the electromagnetic forces, an innovative mechanical structure based on the bladder-and-key concept, incorporating asymmetric coils and both aluminum and stainless steel skins, has been developed at INFN and further studied in collaboration with the University of Patras. This paper describes the design concept of the 16 T twin-aperture dipole magnet and the fully 2D & 3D parametric multi-physics finite & boundary element model (FEM & BEM), including the end regions. The design optimization is described and the optimized assembly parameters are presented.

*Work is supported by CERN, under contract No. FCC-GOV-CC-0141.Speaker: Mr Charilaos Kokkinos (FEAC Engineering P.C. & University of Patras) -

39

Mon-Mo-Po1.04-04 [38]: Electromagnetic and mechanical study for the Nb3Sn bending dipole short model for FCC

The Italian Institute for Nuclear Physics (INFN), in collaboration with CERN, is going to build the short model in Nb3Sn of the main bending dipole for the Future Circular Collider (FCC). The magnet will be developed on the basis of the baseline design presented in the FCC Conceptual Design Report (CDR) in the end of 2018. The magnet is based on cosine-theta design, with an internal aperture diameter of 50 mm and a “Bladder & Key” configuration for the mechanics.

The main purpose of the model construction is to demonstrate the feasibility of a magnet dipole with field quality characteristic suitable for collider and magnetic field above the LHC frontier.

The mechanical structure, which is a critical aspect of the magnet design, especially for the brittleness of the Nb3Sn cables, will have to demonstrate the effectiveness to reach the highest performance achievable in terms of bore magnetic field.

Here we present both the electromagnetic and mechanical design study of the model.Speaker: Riccardo Umberto Valente (LASA-INFN (Milano, Italy)) -

40

Mon-Mo-Po1.04-05 [39]: Quench protection study for F2D2, the Flared-end Block Dipole Demonstrator for the Future Circular Collider

The forecast hadronic synchrotron studied in the FCC-hh program aims to reach 100 TeV center-of-mass collision energy using 16 T bending dipole magnets along a 100 km long ring. Gaining such magnetic field occupying a reasonable volume requires new technologies to be tested and validated on demonstrators. In collaboration with CERN, CEA is developing F2D2, the FCC Flared-end Dipole Demonstrator based on the block-coil option proposed in the EuroCirCol study. This single aperture 1.4 m long magnet is designed to reach at least 15 T with 14% margin at 1.9 K using two different Nb3Sn cables. The energy density per unit length is 1.4 MJ/m, about 3 times the energy density per unit length of the LHC dipoles. The combination of the high energy density and the graded coils makes the quench protection of this magnet one of the most challenging. A study considering the state-of-the-art of active quench protection technologies such as heaters and CLIQ is here presented, completed with multi-physics models to accurately describe the quench evolution, the hotspot temperature and the voltages between and at the end of the coils.

Speaker: Dr Valerio Calvelli (CEA) -

41

Mon-Mo-Po1.04-06 [40]: Presentation withdrawn

-

42

Mon-Mo-Po1.04-08 [41]: Investigations into the preliminary Future Circular collider 16 Tesla dipole cryostat design.

As part of an international collaboration, CERN has recently published a Conceptual Design Review of the Future Circular Collider (FCC), a proposed particle accelerator to succeed the LHC. Under the options considered, a proto-proton accelerator with collision energies up to 100 TeV, would require approximately 4’500 Nb3Sn superconducting dipole magnets operating at 16 T fields, installed in a new tunnel of about 100 km circumference. A proposed variant, as a possible first step towards the FCC, is the incorporation of these magnets in the existing LHC tunnel infrastructure. This will provide a proton-proton collider with about twice the collision energy of the LHC, the so-called High Energy LHC (HE-LHC). The 16 T dipoles, which are considerably larger and heavier than the 8.33 T LHC dipoles, require compact cryostats to keep the overall dimensions comparable with the size of the LHC tunnel.

In this paper, we report on the design and integration work on the baseline 16T cosine-theta design dipole magnets within their cryostats. We present here, possible design options departing from the well-established solution of the LHC cryostats, including mechanical and thermal design considerations on the cryostat. We also explore the electromagnetic and mechanical coupling between the magnet and the vacuum vessel, in the case of a stray field in the cryostat space, as would be required to reduce the volume of the cold mass.Speaker: Zoe Marie Townsend (CERN) -

43

Mon-Mo-Po1.04-10 [42]: Design of an 18 T arc dipole for an LHC energy doubler

We report the design for a hybrid block-coil dipole using advanced cable-in-conduit windings. The dipole is designed for use in the arcs of an energy-doubling lattice in the LHC tunnel.

The block coil design facilitates configuration of hybrid sub-windings of Bi-2212, Nb3Sn, and NbTi, each operating to the same fraction of critical current.

The cryogenics utilizes supercritical helium, operating in the window 4.5-5.5 K.

A novel method is provided for the support structure that provides robust support and stress management, and provides for the three sub-windings to be separately wound and heat-treated and then assembled and preloaded to complete the dipole.Speaker: Peter McIntyre (Texas A&M University) -

44

Mon-Mo-Po1.04-11 [43]: Presentation withdrawn

-

45

Mon-Mo-Po1.04-12 [44]: Mechanical behavior of a dipolar support structure for sextupole-in-solenoid Magnet during assembly, cool-down and warm-up processes

Aiming to develop a combined superconducting magnet for a fourth-generation ECR source operating at 45 GHz at the Institute of Modern Physics (IMP) in Lanzhou of China, a significant gain in performance can be achieved by using Nb3Sn to allow solenoids and sextupole coils to reach a high field of 12 T. In consideration of special design of the sextupole-in-solenoid shape, the supporting structures with pre-tensioned aluminum cylinders named Bladder are used to bear the large loading and maintain the configuration during the magnet assembly and operation in cryogenic and electromagnetic environment. A dipolar structure based on an aluminum shell and home-made bladders were designed in this work. The mechanical characteristics of the dipolar support structure were explored numerically and experimentally. A 3D finite element modeling was developed to analyze the deformation and stresses in the structures during its assembly, cool-down and warm-up for simulating the practical operation conditions. The measurements on the strains profiles in the aluminum shell in the dipolar support structure also has been conducted using low-temperature resistance strain gauges combined with a half-bridge compensation method for temperature. Our results show that the pre-stresses induced in the support structures during the two stages of gas loading in the bladder and shrinkage during cool-down process reach the level for efficiently hustling the 12T superconducting ECR magnet. The numerical analysis is in good agreement with the measurements. Additionally, the mechanical behavior of the bladders during gas loading and cool-down is obviously dependent with the friction property between contact surfaces, which gives the main concerns in the design and optimization such special support structures under cryogenic environment.

Key words: Superconducting magnet, dipolar support structure, bladder, cryogenic environment, mechanical analysisSpeaker: Beimin Wu (1 Key Laboratory of Mechanics on Western Disaster and Environment, College of Civil Engineering and Mechanics, Lanzhou University, China; 2 Institute of Modern Physics of Chinese Academy of Science, China) -

46

Mon-Mo-Po1.04-13 [45]: Fabrication and High-field Performance of the First Iron-Based Superconductor Racetrack Coil

The first 100-m iron-based superconductor (IBS) tape was produced by Institute of Electrical Engineering, Chinese Academy of Sciences (IEE-CAS) using the powder-in-tube technique in 2016. Since then, the development of IBS tape provides an opportunity to propel the practical IBS application. In this study, the world first IBS racetrack coil was made using a 100-m 7-filamentary Ba1-xKxFe2As2 (Ba122) tape at the Institute of High Energy Physics, Chinese Academy of Sciences (IHEP-CAS). The IBS tape was winded in parallel with stainless steel tape before heat reaction and impregnated with epoxy resin after reaction. The performance of the IBS coil was tested at 4.2 K and 0 - 7.5 T background field provided by an Nb3Sn Common-Coil dipole magnet named LPF1.2. The racetrack coil quenched at 7.5 T with operating current of 45.9 A, which is about 64% of the quench current at self-field. And the quench was caused by heat from one joint. The details of fabrication process and performance test results were presented in this paper.

Speaker: Dr Zhan Zhang (IHEP, Chinese Academy of Sciences (CAS) ) -

47

Mon-Mo-Po1.04-14 [46]: Mechanical Design, Assembly and Strain Measurement Results of LPF2: a 12-T Hybrid Common-coil Dipole Magnet

The Institute of High Energy Physics (IHEP, China) has been engaged in the development of shell-based dipole magnet with common-coil configuration for the pre-study of Super proton-proton Collider (SppC) project. The first subscale magnet LPF1, with two Nb3Sn coils and four NbTi coils, reached a bore field of 10.2 T at 4.2 K. Then a higher safety margin model has been proposed as LPF2, which has six Nb3Sn coils and two NbTi coils to reach a 12-T main field in both apertures with an operating current of 5300 A. The shell and yoke are reused from LPF1, as well as the two Nb3Sn coils and two inner NbTi coils of LPF1. The pre-loaded method of LPF2 is much alike that in LPF1: using Bladder & Key technology to overcome the Lorenz force in horizontal and vertical direction and pre-tightening six aluminum rod to pre-load the coil packs in the axial direction. While, the strain gauges are applied both at the surface of the aluminum shell and the inner surface of the innermost coils to monitor the pre-loading effect. The main design parameters, stress analysis, assembly procedure and strain measurement results during the assembly and test at 4.2 K will be presented.

Speaker: Yingzhe Wang (IHEP, CAS) -

48

Mon-Mo-Po1.04-15 [47]: Mechanical analysis and measurements of MQXFS6, the fifth short model of the Nb3Sn Low-β Quadrupole for the Hi-Lumi LHC

MQXF is the Nb3Sn Low-β Quadrupole magnet that the HL-LHC project is planning to install in the LHC interaction regions in 2026 to increase the LHC integrated luminosity by about a factor of ten. The magnet will be fabricated in two different lengths: 4.2 m for MQXFA, built in the US by the Accelerator Upgrade Project (AUP), and 7.15 m for MQXFB, fabricated by CERN. In order to qualify the magnet design and characterize its performance with different conductors, cable geometries and pre-load configuration, five short model magnets, called MQXFS, were fabricated, assembled and tested. The last model, MQXFS6, used a new PIT superconductor, featuring a bundle barrier surrounding the filaments. The coil and the support structure were equipped with strain gauges and optical fibers to monitor strain during assembly, cool-down and excitation. We describe in this paper the mechanical performance of MQXFS6, analysed through experimental data and numerical models, and we compare it with the one of the previous short model magnets.

Speaker: Giorgio Vallone (LBNL)

-

37

-

Mon-Mo-Po1.05 - Fusion I: CFETR & JT-60 Level 2 Posters 2

Level 2 Posters 2

Convener: Jinxing Zheng (Institute of Plasma Physics, Chinese Academy of Sciences)-

49

Mon-Mo-Po1.05-01 [54]: Safety Research of the 100 kA HTS Current Lead for CFETR

Abstract: Based on the Agreement of Institute of Plasma Physics Chinese Academy of Sciences (ASIPP) and Ministry of Science and Technology of China during the Thirteen Five-Years Plan (so called 13∙5 plan), A dedicated test complex of superconducting magnet for China Fusion Engineering Test Reactor (CFETR) will be constructed in Hefei, China. A pair of high temperature superconducting (HTS) current leads rated at 100 kA for the CFETR magnet test complex is being designed at ASIPP. Because magnetic energy stored in the toroidal field magnet is 134 Giga Joules which are 3 times higher than the ITER case, HTS current leads must work in high voltage and nominal current without performance degradation during the magnet quench. In order to verify the safety and reliability of HTS current lead, this paper will numerically simulate the time of loss of flow accident (LOFA) from 50 K helium stoppage to the current sharing temperature starting and the burnout time from the current sharing temperature starting to the hotspot temperature of 200 K or the max. voltage of 100 mV along HTS module. The load line of static magnetic field is presented to predict the maximum current carrying capacity of HTS module. The inhomogeneous current distribution as a function of magnetic field with/without external applied field of 30 mT for the 90 HTS stacks is calculated by ANSYS iteration to estimate the current margin. The analysis results indicate the LOFA time is more than 500 s and the full current burnout time of 30 s is better than the requirement of the toroidal field magnet fast discharge time constant of 20 s, the HTS module heat load is less than 15W.

Index Terms—HTS, Current lead, Safety, CFETR

Acknowledgment: This work was supported by the Research of CFETR Integration Engineering Design Project (Grant No. 2017YFE0300500).Speaker: Dr Kaizhong Ding (Institute of plasma physics, Chinese academy of sciences) -

50

Mon-Mo-Po1.05-02 [55]: CFETR Central Solenoid Magnet System Structural Analysis

Engineering design of China Fusion Engineering Test Reactor (CFETR) Central Solenoid (CS) coil had been started in Institute of Plasma Physics, Chinese Academy of Sciences. The highest field of CS coil is 17.2T when the running current is 60KA. CS magnet system mainly consists of 8 Nb3Sn coils compressed with 8 sets of preload structure. The functions of the preload structure are to apply an enough axial compression to the CS coils and to have a mechanical rigidity against the repulsive force between 8 Nb3Sn coils. This paper describes structural design of CFETR CS magnet system. A global finite element model was created based on the design geometry data to investigate the mechanical property of CFETR CS preload structure and support structure under the different operating conditions. A local finite element model based on structure design was created to calculate the stress on the conductor jacket and turn insulation.

Key words: CFETR, Central Solenoid, structural design, FEA, MagnetSpeaker: Aihua Xu (institute of plasma physics Chinese academy of sciences) -

51

Mon-Mo-Po1.05-03 [56]: Fabrication Status of CFETR Central Solenoid Model Coil

The Central Solenoid Model Coil (CSMC) project of CFETR that began in 2014 is devoted to develop and verify the manufacturing and testing technology of the large-scale superconducting magnet. The main manufacturing processes for the coil are verified by the mockup coil’s fabrication. For now, the winding for the Nb3Sn inner and outer coils are finished and preparing for its heat treatment, and the vacuum pressure impregnation for the NbTi middle coil is being done. This paper introduces the main manufacturing progress of the CFETR CSMC.

Speaker: Houxiang HAN -

52

Mon-Mo-Po1.05-04 [57]: The application of TSTC based on ReBCO tapes in CFETR CS magnet design

In order to further study fusion, China National Integration Design Group designed and developed a new superconducting magnet tokamak device, China Fusion Engineering Test Reactor (CFETR). As one of the most important components of the CFETR, the CS coil will be constructed to create, form and maintain a stable operation of the plasma. The latest CFETR CS magnet system design requirements are as follows:

1) To produce a 12-T peak field in the core of the magnet.

2) The maximum magnetic field on the NbTi module is lower than 6 T.

3) The maximum magnetic field change rate is 1.5 T/s, and the operating current is 47.65 kA.

4) The unit length of one Nb3Sn conductor is shorter than 1 km.

These requirements will bring a series of problems and challenges such as stability margin and mechanical safety to the design work of CS magnets. In recent years, with the development of HTS wires (especially ReBCO tapes), HTS has become an important choice for designing CS magnets in the future. Among the HTS wires, only Bi2212, Bi2223 and ReBCO are considered suitable for large-scale applications. Compared to the former two, ReBCO tapes not only has higher current transfer capability, but also No complicated heat treatment process is required after the strip is wound. Therefore, ReBCO will be one of the important alternatives for the design of CS magnet for fusion device in the future.

In this paper, we first calculate the equivalent material properties of the TSTC based on ReBCO. Then, according to the latest CFETR CS magnet design requirements, a hybrid CS magnet model based on ReBCO, Nb3Sn and NbTi was designed and analyzed. The results will provide reference for the design of high field strength and large current magnets in future fusion devices.Speaker: Mr Yong Ren (Institute of Plasma Physics, Chinese Academy of Sciences) -

53

Mon-Mo-Po1.05-05 [58]: Seismic analysis of the CFETR central solenoid model coil